Popular Models of Common Overload Capacitors

I. Introduction

A. Definition of Overload Capacitors

Overload capacitors are essential components in electrical systems, designed to manage excess voltage and current. They play a critical role in stabilizing electrical circuits, ensuring that devices operate efficiently and safely. By temporarily storing electrical energy, these capacitors help to smooth out fluctuations in power supply, protecting sensitive equipment from damage.

B. Importance of Overload Capacitors in Electrical Systems

In various applications, overload capacitors are vital for maintaining the reliability and longevity of electrical systems. They are commonly found in industrial machinery, consumer electronics, and renewable energy systems. Their ability to handle transient voltages and currents makes them indispensable in preventing equipment failure and enhancing overall system performance.

C. Purpose of the Article

This article aims to provide an in-depth understanding of overload capacitors, their applications, popular models, and factors to consider when selecting the right capacitor for specific needs. By exploring these aspects, readers will gain valuable insights into the importance of overload capacitors in modern electrical systems.

II. Understanding Overload Capacitors

A. What are Overload Capacitors?

1. Function and Role in Electrical Circuits

Overload capacitors serve to absorb excess energy during voltage spikes, thereby protecting circuits from damage. They act as a buffer, allowing for a smoother flow of electricity and reducing the risk of overload conditions that can lead to equipment failure.

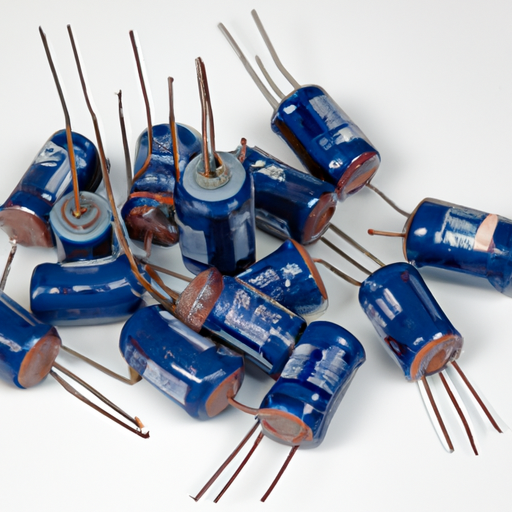

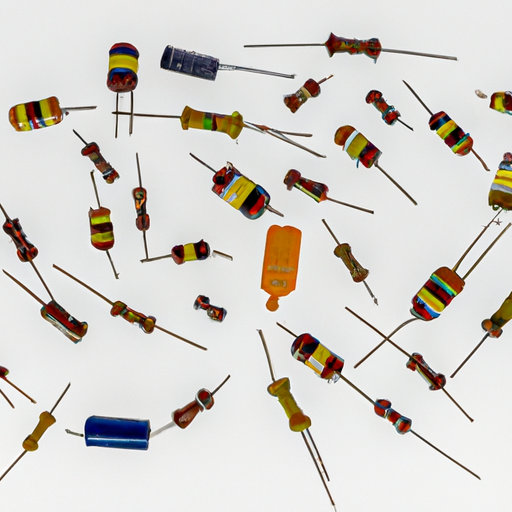

2. Types of Overload Capacitors

There are several types of overload capacitors, including electrolytic, ceramic, and film capacitors. Each type has its unique characteristics and is suited for different applications. For instance, electrolytic capacitors are often used in power supply circuits due to their high capacitance values, while ceramic capacitors are favored for their stability and reliability in high-frequency applications.

B. Key Specifications

1. Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can handle without failing. Selecting a capacitor with an appropriate voltage rating is crucial to ensure safe operation.

2. Capacitance Value

Capacitance value, measured in farads, determines how much electrical energy a capacitor can store. The required capacitance value depends on the specific application and the amount of energy that needs to be managed.

3. Temperature Rating

Temperature ratings indicate the range of temperatures within which a capacitor can operate effectively. Capacitors with higher temperature ratings are essential for applications in extreme environments.

4. Tolerance Levels

Tolerance levels specify the allowable variation in capacitance from the stated value. A lower tolerance level indicates a more precise capacitor, which is often necessary for sensitive applications.

III. Common Applications of Overload Capacitors

A. Industrial Applications

1. Motors and Drives

In industrial settings, overload capacitors are commonly used in motors and drives to manage inrush currents and voltage spikes. They help to ensure smooth operation and prevent damage to motor windings.

2. Power Supply Systems

Overload capacitors are integral to power supply systems, where they stabilize voltage levels and improve overall efficiency. They help to filter out noise and provide a steady power supply to critical equipment.

B. Consumer Electronics

1. Home Appliances

In home appliances, overload capacitors are used to enhance performance and reliability. They help to manage power surges, ensuring that devices like refrigerators and washing machines operate smoothly.

2. Audio Equipment

High-fidelity audio equipment often employs overload capacitors to maintain sound quality. They help to filter out unwanted noise and provide a stable power supply to amplifiers and speakers.

C. Renewable Energy Systems

1. Solar Inverters

In solar energy systems, overload capacitors are used in inverters to manage fluctuations in power output. They help to ensure that the energy produced is stable and usable.

2. Wind Turbines

Wind turbines also utilize overload capacitors to manage the variable nature of wind energy. These capacitors help to smooth out power delivery, making it more consistent and reliable.

IV. Popular Models of Overload Capacitors

A. Overview of Leading Manufacturers

1. Manufacturer A

Manufacturer A is known for its high-quality overload capacitors, offering a range of products designed for various applications. Their product line includes electrolytic and film capacitors, known for their reliability and performance.

Popular Models: Model A1, Model A2, Model A3

2. Manufacturer B

Manufacturer B specializes in ceramic capacitors, providing solutions for high-frequency applications. Their capacitors are widely used in consumer electronics and industrial equipment.

Popular Models: Model B1, Model B2, Model B3

3. Manufacturer C

Manufacturer C focuses on renewable energy applications, offering capacitors specifically designed for solar and wind energy systems. Their products are known for their durability and efficiency.

Popular Models: Model C1, Model C2, Model C3

B. Detailed Analysis of Selected Models

1. Model 1

Specifications: 100µF, 250V, ±10% tolerance, temperature range -40°C to 85°C

Applications: Suitable for industrial motors and power supply systems.

Advantages and Disadvantages: High capacitance value; however, it may be bulkier than other models.

2. Model 2

Specifications: 10µF, 50V, ±5% tolerance, temperature range -25°C to 70°C

Applications: Ideal for consumer electronics and audio equipment.

Advantages and Disadvantages: Compact size and high precision; limited voltage rating.

3. Model 3

Specifications: 220µF, 400V, ±20% tolerance, temperature range -40°C to 105°C

Applications: Designed for renewable energy systems, particularly solar inverters.

Advantages and Disadvantages: Excellent temperature tolerance; however, it may be more expensive than standard models.

V. Factors to Consider When Choosing Overload Capacitors

A. Application Requirements

Understanding the specific requirements of the application is crucial when selecting an overload capacitor. Factors such as voltage, capacitance, and environmental conditions must be considered.

B. Environmental Conditions

Capacitors must be chosen based on the environmental conditions they will face, including temperature extremes, humidity, and exposure to chemicals.

C. Cost vs. Performance

Balancing cost and performance is essential. While high-performance capacitors may offer better reliability, they can also be more expensive. It's important to find a suitable compromise.

D. Reliability and Longevity

Selecting capacitors known for their reliability and longevity can save costs in the long run by reducing the need for replacements and maintenance.

VI. Maintenance and Troubleshooting

A. Signs of Overload Capacitor Failure

Common signs of capacitor failure include bulging, leaking, or discoloration. Additionally, if equipment experiences frequent power surges or malfunctions, it may indicate a failing capacitor.

B. Best Practices for Maintenance

Regular inspection and testing of overload capacitors can help identify potential issues before they lead to failure. Keeping capacitors clean and ensuring proper installation can also enhance their lifespan.

C. Troubleshooting Common Issues

If a capacitor fails, troubleshooting may involve checking for proper voltage levels, inspecting connections, and replacing faulty components. It's essential to follow safety protocols when handling electrical components.

VII. Future Trends in Overload Capacitor Technology

A. Innovations in Materials and Design

Advancements in materials science are leading to the development of more efficient and durable capacitors. New materials can enhance performance and reduce size, making capacitors more versatile.

B. Impact of Smart Technology

The integration of smart technology in electrical systems is driving demand for advanced capacitors that can communicate and adapt to changing conditions. This trend is expected to continue as smart grids and IoT devices become more prevalent.

C. Sustainability and Environmental Considerations

As environmental concerns grow, manufacturers are focusing on creating more sustainable capacitor solutions. This includes using eco-friendly materials and designing capacitors for recyclability.

VIII. Conclusion

A. Recap of Key Points

Overload capacitors are critical components in electrical systems, providing stability and protection against voltage spikes. Understanding their specifications, applications, and popular models is essential for selecting the right capacitor for specific needs.

B. Importance of Selecting the Right Overload Capacitor

Choosing the appropriate overload capacitor can significantly impact the performance and reliability of electrical systems. It is crucial to consider application requirements, environmental conditions, and cost versus performance.

C. Final Thoughts on the Future of Overload Capacitors

As technology continues to evolve, the role of overload capacitors will become increasingly important. Innovations in materials, smart technology integration, and sustainability efforts will shape the future of these essential components.

IX. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Catalogs

This comprehensive overview of popular models of common overload capacitors highlights their significance in various applications and provides valuable insights for selecting the right capacitor for specific needs. By understanding the key specifications and trends in capacitor technology, readers can make informed decisions that enhance the performance and reliability of their electrical systems.

Understanding High-Voltage Parallel Capacitors

I. Introduction

High-voltage parallel capacitors are essential components in various electrical systems, playing a crucial role in energy storage, voltage regulation, and power factor correction. As the demand for efficient and reliable electrical systems continues to grow, understanding these capacitors becomes increasingly important. This article aims to provide a comprehensive overview of high-voltage parallel capacitors, their construction, applications, safety considerations, and future trends.

II. Basics of Capacitors

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are widely used in electronic circuits for various functions, including filtering, timing, and energy storage.

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply circuits due to their high capacitance values.

2. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are commonly used in high-frequency applications.

3. **Film Capacitors**: These capacitors are made from thin plastic films and are known for their low losses and high insulation resistance.

4. **High-Voltage Capacitors**: Designed to operate at high voltage levels, these capacitors are crucial in applications where voltage ratings exceed standard levels.

C. Capacitance and Its Measurement

Capacitance is the ability of a capacitor to store charge, measured in farads (F). The capacitance value depends on several factors, including the surface area of the plates, the distance between them, and the type of dielectric material used. Understanding capacitance is vital for selecting the right capacitor for a specific application.

III. High-Voltage Capacitors

A. Definition and Characteristics

High-voltage capacitors are designed to operate safely at voltages significantly higher than standard capacitors. They are classified based on their voltage ratings, which can range from several hundred volts to several kilovolts. These capacitors are essential in high-voltage systems, where they help manage energy storage and voltage stability.

B. Construction and Materials

The construction of high-voltage capacitors involves specialized materials to ensure safety and reliability. Common dielectric materials include polypropylene, polyester, and ceramic, which can withstand high electric fields without breaking down. Design considerations for high-voltage applications include ensuring adequate insulation, thermal management, and mechanical stability.

IV. Parallel Capacitors

A. Definition of Parallel Capacitors

When capacitors are connected in parallel, their terminals are connected to the same voltage source, allowing them to share the load. This configuration increases the total capacitance while maintaining the same voltage rating.

B. Benefits of Using Capacitors in Parallel

1. **Increased Capacitance**: The total capacitance of capacitors in parallel is the sum of their individual capacitances, allowing for greater energy storage.

2. **Improved Voltage Handling**: Parallel configurations can handle higher voltage levels, making them suitable for high-voltage applications.

3. **Enhanced Reliability and Redundancy**: If one capacitor fails, the others can continue to function, improving the overall reliability of the system.

C. Mathematical Principles of Parallel Capacitors

The total capacitance (C_total) of capacitors connected in parallel can be calculated using the formula:

\[ C_{total} = C_1 + C_2 + C_3 + ... + C_n \]

This principle is crucial for circuit design, as it allows engineers to determine the required capacitance for specific applications.

V. Applications of High-Voltage Parallel Capacitors

A. Power Systems

High-voltage parallel capacitors are widely used in power systems for:

1. **Energy Storage and Power Factor Correction**: They help store excess energy and improve the power factor, reducing losses in the system.

2. **Voltage Regulation and Stability**: By providing reactive power support, these capacitors help maintain voltage levels within acceptable limits.

B. Industrial Applications

In industrial settings, high-voltage parallel capacitors are used in:

1. **Motor Drives and Inverters**: They smooth out voltage fluctuations and provide stable operation for electric motors and inverters.

2. **High-Voltage Transmission Lines**: Capacitors are used to compensate for reactive power losses in long-distance transmission lines.

C. Renewable Energy Systems

High-voltage parallel capacitors play a vital role in renewable energy systems, including:

1. **Integration with Solar and Wind Energy Systems**: They help manage the variable output of renewable sources, ensuring a stable supply of energy.

2. **Role in Energy Storage Solutions**: Capacitors are used in conjunction with batteries and other storage technologies to enhance overall system performance.

VI. Safety Considerations

A. Risks Associated with High-Voltage Capacitors

Working with high-voltage capacitors poses several risks, including:

1. **Electric Shock Hazards**: High-voltage capacitors can store significant amounts of energy, posing a risk of electric shock if not handled properly.

2. **Thermal Runaway and Failure Modes**: If a capacitor fails, it can lead to thermal runaway, resulting in catastrophic failure and potential hazards.

B. Best Practices for Handling and Installation

To ensure safety when working with high-voltage capacitors, follow these best practices:

1. **Proper Insulation and Grounding**: Ensure that all components are adequately insulated and grounded to prevent accidental contact with live parts.

2. **Use of Protective Equipment**: Always wear appropriate personal protective equipment (PPE) when handling high-voltage capacitors.

VII. Future Trends and Innovations

A. Advances in Capacitor Technology

The field of capacitor technology is continually evolving, with several exciting trends:

1. **New Materials and Designs**: Researchers are exploring advanced materials that offer higher capacitance and better performance at high voltages.

2. **Miniaturization and Efficiency Improvements**: The trend towards smaller, more efficient capacitors is driven by the demand for compact electronic devices and systems.

B. Impact of Emerging Technologies

Emerging technologies, such as electric vehicles and smart grids, are influencing the development of high-voltage capacitors:

1. **Electric Vehicles and Energy Storage Systems**: Capacitors are becoming increasingly important in energy storage solutions for electric vehicles, providing quick bursts of power.

2. **Smart Grid Applications**: High-voltage capacitors are essential for managing the complexities of smart grids, ensuring efficient energy distribution and stability.

VIII. Conclusion

High-voltage parallel capacitors are vital components in modern electrical systems, providing essential functions in energy storage, voltage regulation, and power factor correction. Understanding their construction, applications, and safety considerations is crucial for anyone working in the electrical engineering field. As technology continues to advance, the role of capacitors will only become more significant, making it essential for professionals to stay informed about the latest developments in this area.

IX. References

For further reading and resources on high-voltage capacitors, consider exploring the following:

1. "Capacitor Technology: A Comprehensive Guide" - A detailed book covering various types of capacitors and their applications.

2. IEEE Standards for Capacitors - Industry standards and guidelines related to high-voltage capacitors.

3. Online courses and webinars on capacitor technology and applications in electrical engineering.

By delving deeper into these resources, readers can enhance their understanding of high-voltage parallel capacitors and their critical role in electrical systems.

What are the Latest Pulse Capacitors and Equipment Components Procurement Models?

I. Introduction

Pulse capacitors are specialized components designed to handle rapid changes in voltage and current, making them essential in various high-performance applications. These capacitors are crucial in industries ranging from power electronics to medical devices, where reliability and efficiency are paramount. As the demand for advanced electronic systems grows, so does the complexity of procuring the necessary components, including pulse capacitors. This blog post will explore the latest trends in pulse capacitors and the evolving procurement models that support their acquisition.

II. Understanding Pulse Capacitors

A. Types of Pulse Capacitors

Pulse capacitors come in several types, each with unique characteristics suited for specific applications:

1. **Film Capacitors**: Known for their stability and low ESR, film capacitors are widely used in power electronics and RF applications. They can handle high voltage and current levels, making them ideal for pulse applications.

2. **Ceramic Capacitors**: These capacitors are compact and offer high capacitance values in small packages. They are commonly used in RF applications and are known for their reliability and performance.

3. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in medical devices and automotive systems where space is limited, and reliability is critical.

B. Key Characteristics and Specifications

When selecting pulse capacitors, several key specifications must be considered:

1. **Voltage Rating**: The maximum voltage a capacitor can handle without failure. It is crucial to choose a capacitor with a voltage rating that exceeds the application's requirements.

2. **Capacitance Value**: This indicates the capacitor's ability to store charge. The required capacitance value will depend on the specific application and its energy storage needs.

3. **Equivalent Series Resistance (ESR)**: A measure of the resistance encountered by the current flowing through the capacitor. Lower ESR values are preferred for high-frequency applications to minimize energy loss.

4. **Ripple Current Handling**: The ability of a capacitor to handle AC currents superimposed on the DC voltage. This is particularly important in power electronics where pulsed signals are common.

C. Applications of Pulse Capacitors

Pulse capacitors find applications in various fields:

1. **Power Electronics**: Used in inverters, converters, and power supplies to manage energy storage and delivery efficiently.

2. **RF Applications**: Essential in communication devices, pulse capacitors help maintain signal integrity and performance.

3. **Medical Devices**: In devices like defibrillators and imaging equipment, pulse capacitors ensure reliable operation under critical conditions.

4. **Automotive Systems**: Used in electric vehicles and advanced driver-assistance systems (ADAS), pulse capacitors contribute to the performance and safety of modern vehicles.

III. Evolution of Procurement Models

A. Traditional Procurement Models

Historically, procurement models in the electronics industry have been straightforward:

1. **Direct Purchasing**: Companies would purchase components directly from manufacturers or distributors, often in bulk to secure lower prices.

2. **Bulk Buying**: This model involves purchasing large quantities of components to reduce costs, but it can lead to excess inventory and increased holding costs.

B. Shift Towards Modern Procurement Strategies

The landscape of procurement is evolving, with companies adopting more sophisticated strategies:

1. **Just-in-Time (JIT) Procurement**: This model minimizes inventory costs by ordering components only as needed. JIT helps companies respond quickly to market demands but requires a reliable supply chain.

2. **Vendor-Managed Inventory (VMI)**: In this model, suppliers manage the inventory levels of their products at the buyer's location. This approach can enhance efficiency and reduce stockouts.

3. **E-Procurement Systems**: Digital platforms streamline the procurement process, allowing companies to manage orders, track inventory, and analyze spending more effectively.

IV. Latest Trends in Pulse Capacitor Procurement

A. Increased Focus on Sustainability

As environmental concerns grow, the electronics industry is placing greater emphasis on sustainability:

1. **Eco-Friendly Materials**: Manufacturers are exploring the use of biodegradable and recyclable materials in capacitor production to reduce environmental impact.

2. **Lifecycle Assessment**: Companies are increasingly evaluating the environmental impact of components throughout their lifecycle, from production to disposal.

B. Digital Transformation in Procurement

The integration of technology is reshaping procurement processes:

1. **Use of AI and Machine Learning**: These technologies help companies analyze data, predict demand, and optimize supplier selection, leading to more informed procurement decisions.

2. **Blockchain for Supply Chain Transparency**: Blockchain technology enhances traceability and transparency in the supply chain, helping to ensure the authenticity and quality of components.

C. Collaborative Procurement Models

Collaboration is becoming a key strategy in procurement:

1. **Strategic Partnerships with Suppliers**: Companies are forming long-term relationships with suppliers to ensure a reliable supply of high-quality components.

2. **Consortium Buying**: By pooling resources with other companies, organizations can negotiate better prices and terms for bulk purchases of pulse capacitors.

V. Challenges in Pulse Capacitor Procurement

Despite advancements, several challenges persist in the procurement of pulse capacitors:

A. Supply Chain Disruptions

1. **Global Semiconductor Shortages**: The ongoing semiconductor shortage has affected the availability of many electronic components, including pulse capacitors.

2. **Geopolitical Factors**: Trade tensions and geopolitical instability can disrupt supply chains, leading to delays and increased costs.

B. Quality Assurance and Testing

1. **Ensuring Reliability and Performance**: As applications become more demanding, ensuring the quality and reliability of pulse capacitors is critical.

2. **Compliance with Industry Standards**: Manufacturers must adhere to strict industry standards, which can complicate the procurement process.

C. Cost Management

1. **Balancing Quality and Price**: Companies must navigate the trade-off between cost and quality, ensuring they procure reliable components without overspending.

2. **Long-Term vs. Short-Term Procurement Strategies**: Organizations must decide whether to invest in long-term contracts for stability or adopt flexible strategies to respond to market fluctuations.

VI. Case Studies

A. Successful Implementation of Modern Procurement Models

1. **Company A: Adopting JIT for Pulse Capacitors**: By implementing a JIT procurement strategy, Company A reduced inventory costs and improved responsiveness to market changes, leading to increased customer satisfaction.

2. **Company B: Leveraging AI for Supplier Selection**: Company B utilized AI algorithms to analyze supplier performance data, resulting in more informed decisions and improved supplier relationships.

B. Lessons Learned from Procurement Failures

1. **Company C: Challenges Faced During a Supply Chain Crisis**: Company C experienced significant delays and increased costs due to a lack of diversification in its supplier base, highlighting the importance of risk management in procurement.

VII. Future Outlook

A. Predictions for Pulse Capacitor Technology Advancements

As technology continues to evolve, we can expect advancements in pulse capacitor design, including higher capacitance values, improved energy density, and enhanced thermal performance.

B. Anticipated Changes in Procurement Models

The procurement landscape will likely continue to shift towards more collaborative and technology-driven approaches, with an emphasis on sustainability and supply chain resilience.

C. The Role of Innovation in Shaping Future Procurement Strategies

Innovation will play a crucial role in developing new procurement strategies, enabling companies to adapt to changing market conditions and consumer demands.

VIII. Conclusion

Pulse capacitors are vital components in modern electronics, and understanding the latest procurement models is essential for organizations looking to stay competitive. As the industry evolves, stakeholders must adapt to new trends and technologies to ensure efficient and sustainable procurement practices. By embracing innovation and collaboration, companies can navigate the challenges of the procurement landscape and secure the components necessary for their success.

The 10 Most Popular Models of Mainstream Ceramic Capacitors

Introduction

Ceramic capacitors are essential components in modern electronic circuits, playing a crucial role in filtering, decoupling, and energy storage. Their reliability, stability, and versatility make them a preferred choice for various applications, from consumer electronics to automotive systems. Understanding the different models of ceramic capacitors and their specific applications is vital for engineers and designers. This article explores the ten most popular models of mainstream ceramic capacitors, highlighting their specifications, applications, and unique features.

1. Understanding Ceramic Capacitors

1.1 Definition and Function

Ceramic capacitors are passive electronic components that store electrical energy in an electric field. They consist of a ceramic dielectric material sandwiched between conductive plates. When voltage is applied, the capacitor stores energy, which can be released when needed. Their primary functions include filtering noise, stabilizing voltage, and providing energy storage in various electronic circuits.

1.2 Types of Ceramic Capacitors

Ceramic capacitors are categorized into two main classes: Class 1 and Class 2.

Class 1 capacitors (e.g., C0G/NP0) offer high stability and low loss, making them suitable for precision applications. They have a linear capacitance change with temperature and voltage.

Class 2 capacitors (e.g., X7R, Y5V) provide higher capacitance values in smaller sizes but have more significant variations in capacitance with temperature and voltage. They are commonly used in applications where size and capacitance are more critical than precision.

2. Key Parameters of Ceramic Capacitors

2.1 Capacitance Value

Capacitance is measured in farads (F), with common values for ceramic capacitors ranging from picofarads (pF) to microfarads (µF). The capacitance value is crucial in circuit design, as it determines how much charge the capacitor can store and how it will behave in a circuit.

2.2 Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. Selecting the appropriate voltage rating is essential to ensure reliability and prevent failure in high-voltage applications.

2.3 Temperature Coefficient

Temperature coefficients, such as X7R and C0G, describe how capacitance changes with temperature. For instance, X7R capacitors can vary by ±15% over a temperature range, while C0G capacitors maintain their capacitance within ±5%. Understanding these coefficients helps in selecting the right capacitor for temperature-sensitive applications.

2.4 Size and Form Factor

Ceramic capacitors come in various sizes and form factors, with common package types including 0402, 0603, and 0805. The physical dimensions are relevant in design, especially in compact electronic devices where space is limited.

3. The 10 Most Popular Models of Mainstream Ceramic Capacitors

3.1 Model 1: Murata GRM Series

The Murata GRM series is renowned for its reliability and performance. These capacitors are available in various capacitance values and voltage ratings, making them suitable for a wide range of applications, including smartphones and automotive electronics. Their compact size and excellent temperature stability make them a popular choice among engineers.

3.2 Model 2: TDK C3216 Series

The TDK C3216 series offers high capacitance values in a small package, making them ideal for space-constrained applications. With a wide voltage range and good temperature characteristics, these capacitors are commonly used in consumer electronics and industrial applications.

3.3 Model 3: Kemet C4 Series

Kemet's C4 series capacitors are known for their high capacitance and low ESR (Equivalent Series Resistance). They are widely used in power supply circuits and decoupling applications, providing excellent performance in demanding environments.

3.4 Model 4: Vishay VJ Series

The Vishay VJ series features a broad range of capacitance values and voltage ratings. These capacitors are designed for high-frequency applications, making them suitable for RF circuits and telecommunications equipment. Their reliability and performance make them a favorite among engineers.

3.5 Model 5: AVX 0805 Series

The AVX 0805 series capacitors are compact and versatile, offering a range of capacitance values and voltage ratings. They are commonly used in consumer electronics, automotive applications, and industrial machinery, providing reliable performance in various environments.

3.6 Model 6: Panasonic ECJ Series

Panasonic's ECJ series capacitors are known for their high reliability and stability. They are available in various capacitance values and are widely used in audio equipment, power supplies, and automotive electronics. Their excellent temperature characteristics make them suitable for demanding applications.

3.7 Model 7: Nichicon UHE Series

The Nichicon UHE series capacitors are designed for high-performance applications, offering low ESR and high ripple current capabilities. They are commonly used in power supply circuits and audio equipment, providing reliable performance in critical applications.

3.8 Model 8: Samsung CL Series

The Samsung CL series capacitors are compact and offer a wide range of capacitance values. They are suitable for various applications, including consumer electronics and automotive systems. Their reliability and performance make them a popular choice among designers.

3.9 Model 9: WIMA MKS Series

The WIMA MKS series capacitors are known for their high-quality construction and excellent performance. They are widely used in audio applications, power supplies, and industrial machinery, providing reliable performance in demanding environments.

3.10 Model 10: Rubycon ZLJ Series

The Rubycon ZLJ series capacitors are designed for high-performance applications, offering low ESR and high ripple current capabilities. They are commonly used in power supply circuits and audio equipment, providing reliable performance in critical applications.

4. Comparison of the Models

4.1 Performance Metrics

When comparing these models, it's essential to consider capacitance, voltage ratings, and temperature coefficients. For instance, while the Murata GRM series excels in stability, the Kemet C4 series offers higher capacitance values. Understanding these metrics helps engineers select the right capacitor for their specific needs.

4.2 Cost Considerations

Pricing trends for ceramic capacitors can vary significantly based on brand, specifications, and market demand. Generally, higher-quality capacitors with better performance metrics tend to be more expensive. However, the cost should be weighed against the performance and reliability required for the application.

4.3 Availability and Distribution

Most of these models are widely available through major distributors and online platforms. Companies like Digi-Key, Mouser, and Newark offer a broad selection of ceramic capacitors, making it easy for engineers to source the components they need.

5. Applications of Ceramic Capacitors

5.1 Consumer Electronics

Ceramic capacitors play a vital role in consumer electronics, including smartphones, tablets, and laptops. They are used for decoupling, filtering, and energy storage, ensuring stable performance in compact devices.

5.2 Automotive Industry

In the automotive industry, ceramic capacitors are essential for various electronic systems, including engine control units, infotainment systems, and safety features. Their reliability and performance in harsh environments make them a preferred choice for automotive applications.

5.3 Industrial Applications

Ceramic capacitors are widely used in industrial machinery and automation systems. They provide reliable performance in power supply circuits, motor drives, and control systems, ensuring efficient operation in demanding environments.

5.4 Telecommunications

In telecommunications, ceramic capacitors are crucial for communication devices and infrastructure. They are used in RF circuits, signal processing, and power supply applications, ensuring reliable performance in critical communication systems.

6. Future Trends in Ceramic Capacitors

6.1 Technological Advancements

The future of ceramic capacitors is promising, with ongoing innovations in materials and manufacturing processes. Advances in miniaturization are leading to smaller, more efficient capacitors that can meet the demands of modern electronics.

6.2 Market Trends

The market for ceramic capacitors is expected to grow, driven by increasing demand in consumer electronics, automotive, and industrial applications. Emerging technologies, such as electric vehicles and IoT devices, will further fuel this growth, creating new opportunities for capacitor manufacturers.

Conclusion

Ceramic capacitors are indispensable components in modern electronics, offering reliability, stability, and versatility across various applications. Understanding the different models and their specifications is crucial for engineers and designers to select the right capacitor for their needs. As technology continues to advance, the demand for high-performance ceramic capacitors will only increase, making it essential to stay informed about the latest trends and innovations in the field. For those interested in exploring further, a wealth of resources and literature is available to deepen your understanding of ceramic capacitors and their applications.

References

- Manufacturer datasheets and technical specifications for each capacitor model.

- Industry publications and articles on ceramic capacitor technology and applications.

- Online resources and forums for engineers and designers in the electronics field.