What are the Latest Pulse Capacitors and Equipment Components Procurement Models?

I. Introduction

Pulse capacitors are specialized components designed to handle rapid changes in voltage and current, making them essential in various high-performance applications. These capacitors are crucial in industries ranging from power electronics to medical devices, where reliability and efficiency are paramount. As the demand for advanced electronic systems grows, so does the complexity of procuring the necessary components, including pulse capacitors. This blog post will explore the latest trends in pulse capacitors and the evolving procurement models that support their acquisition.

II. Understanding Pulse Capacitors

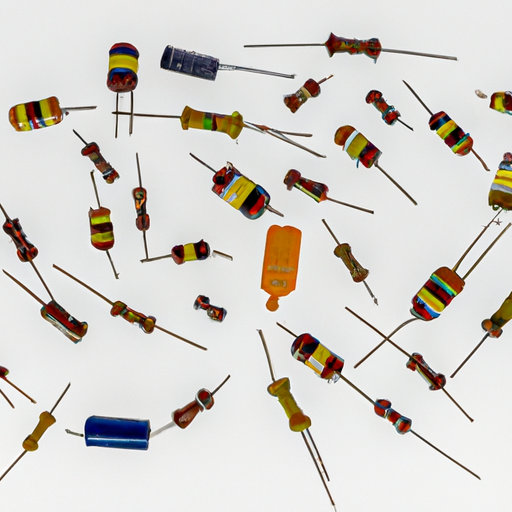

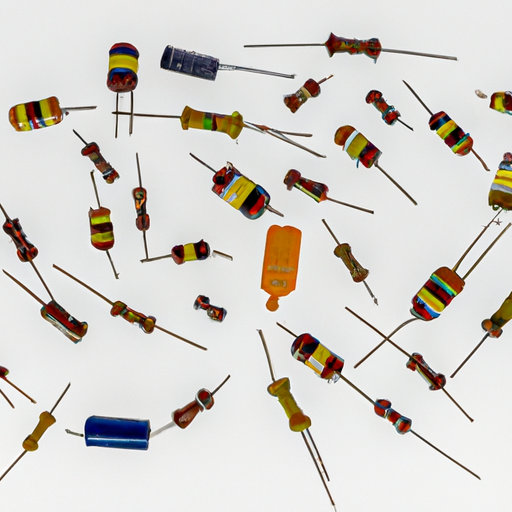

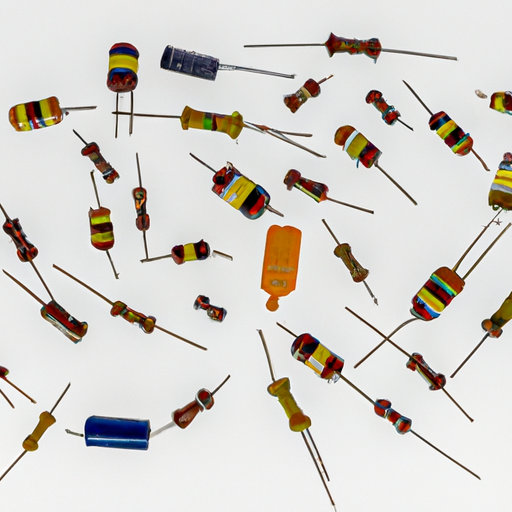

A. Types of Pulse Capacitors

Pulse capacitors come in several types, each with unique characteristics suited for specific applications:

1. **Film Capacitors**: Known for their stability and low ESR, film capacitors are widely used in power electronics and RF applications. They can handle high voltage and current levels, making them ideal for pulse applications.

2. **Ceramic Capacitors**: These capacitors are compact and offer high capacitance values in small packages. They are commonly used in RF applications and are known for their reliability and performance.

3. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in medical devices and automotive systems where space is limited, and reliability is critical.

B. Key Characteristics and Specifications

When selecting pulse capacitors, several key specifications must be considered:

1. **Voltage Rating**: The maximum voltage a capacitor can handle without failure. It is crucial to choose a capacitor with a voltage rating that exceeds the application's requirements.

2. **Capacitance Value**: This indicates the capacitor's ability to store charge. The required capacitance value will depend on the specific application and its energy storage needs.

3. **Equivalent Series Resistance (ESR)**: A measure of the resistance encountered by the current flowing through the capacitor. Lower ESR values are preferred for high-frequency applications to minimize energy loss.

4. **Ripple Current Handling**: The ability of a capacitor to handle AC currents superimposed on the DC voltage. This is particularly important in power electronics where pulsed signals are common.

C. Applications of Pulse Capacitors

Pulse capacitors find applications in various fields:

1. **Power Electronics**: Used in inverters, converters, and power supplies to manage energy storage and delivery efficiently.

2. **RF Applications**: Essential in communication devices, pulse capacitors help maintain signal integrity and performance.

3. **Medical Devices**: In devices like defibrillators and imaging equipment, pulse capacitors ensure reliable operation under critical conditions.

4. **Automotive Systems**: Used in electric vehicles and advanced driver-assistance systems (ADAS), pulse capacitors contribute to the performance and safety of modern vehicles.

III. Evolution of Procurement Models

A. Traditional Procurement Models

Historically, procurement models in the electronics industry have been straightforward:

1. **Direct Purchasing**: Companies would purchase components directly from manufacturers or distributors, often in bulk to secure lower prices.

2. **Bulk Buying**: This model involves purchasing large quantities of components to reduce costs, but it can lead to excess inventory and increased holding costs.

B. Shift Towards Modern Procurement Strategies

The landscape of procurement is evolving, with companies adopting more sophisticated strategies:

1. **Just-in-Time (JIT) Procurement**: This model minimizes inventory costs by ordering components only as needed. JIT helps companies respond quickly to market demands but requires a reliable supply chain.

2. **Vendor-Managed Inventory (VMI)**: In this model, suppliers manage the inventory levels of their products at the buyer's location. This approach can enhance efficiency and reduce stockouts.

3. **E-Procurement Systems**: Digital platforms streamline the procurement process, allowing companies to manage orders, track inventory, and analyze spending more effectively.

IV. Latest Trends in Pulse Capacitor Procurement

A. Increased Focus on Sustainability

As environmental concerns grow, the electronics industry is placing greater emphasis on sustainability:

1. **Eco-Friendly Materials**: Manufacturers are exploring the use of biodegradable and recyclable materials in capacitor production to reduce environmental impact.

2. **Lifecycle Assessment**: Companies are increasingly evaluating the environmental impact of components throughout their lifecycle, from production to disposal.

B. Digital Transformation in Procurement

The integration of technology is reshaping procurement processes:

1. **Use of AI and Machine Learning**: These technologies help companies analyze data, predict demand, and optimize supplier selection, leading to more informed procurement decisions.

2. **Blockchain for Supply Chain Transparency**: Blockchain technology enhances traceability and transparency in the supply chain, helping to ensure the authenticity and quality of components.

C. Collaborative Procurement Models

Collaboration is becoming a key strategy in procurement:

1. **Strategic Partnerships with Suppliers**: Companies are forming long-term relationships with suppliers to ensure a reliable supply of high-quality components.

2. **Consortium Buying**: By pooling resources with other companies, organizations can negotiate better prices and terms for bulk purchases of pulse capacitors.

V. Challenges in Pulse Capacitor Procurement

Despite advancements, several challenges persist in the procurement of pulse capacitors:

A. Supply Chain Disruptions

1. **Global Semiconductor Shortages**: The ongoing semiconductor shortage has affected the availability of many electronic components, including pulse capacitors.

2. **Geopolitical Factors**: Trade tensions and geopolitical instability can disrupt supply chains, leading to delays and increased costs.

B. Quality Assurance and Testing

1. **Ensuring Reliability and Performance**: As applications become more demanding, ensuring the quality and reliability of pulse capacitors is critical.

2. **Compliance with Industry Standards**: Manufacturers must adhere to strict industry standards, which can complicate the procurement process.

C. Cost Management

1. **Balancing Quality and Price**: Companies must navigate the trade-off between cost and quality, ensuring they procure reliable components without overspending.

2. **Long-Term vs. Short-Term Procurement Strategies**: Organizations must decide whether to invest in long-term contracts for stability or adopt flexible strategies to respond to market fluctuations.

VI. Case Studies

A. Successful Implementation of Modern Procurement Models

1. **Company A: Adopting JIT for Pulse Capacitors**: By implementing a JIT procurement strategy, Company A reduced inventory costs and improved responsiveness to market changes, leading to increased customer satisfaction.

2. **Company B: Leveraging AI for Supplier Selection**: Company B utilized AI algorithms to analyze supplier performance data, resulting in more informed decisions and improved supplier relationships.

B. Lessons Learned from Procurement Failures

1. **Company C: Challenges Faced During a Supply Chain Crisis**: Company C experienced significant delays and increased costs due to a lack of diversification in its supplier base, highlighting the importance of risk management in procurement.

VII. Future Outlook

A. Predictions for Pulse Capacitor Technology Advancements

As technology continues to evolve, we can expect advancements in pulse capacitor design, including higher capacitance values, improved energy density, and enhanced thermal performance.

B. Anticipated Changes in Procurement Models

The procurement landscape will likely continue to shift towards more collaborative and technology-driven approaches, with an emphasis on sustainability and supply chain resilience.

C. The Role of Innovation in Shaping Future Procurement Strategies

Innovation will play a crucial role in developing new procurement strategies, enabling companies to adapt to changing market conditions and consumer demands.

VIII. Conclusion

Pulse capacitors are vital components in modern electronics, and understanding the latest procurement models is essential for organizations looking to stay competitive. As the industry evolves, stakeholders must adapt to new trends and technologies to ensure efficient and sustainable procurement practices. By embracing innovation and collaboration, companies can navigate the challenges of the procurement landscape and secure the components necessary for their success.

What are the Latest Pulse Capacitors and Equipment Components Procurement Models?

I. Introduction

Pulse capacitors are specialized components designed to handle rapid changes in voltage and current, making them essential in various high-performance applications. These capacitors are crucial in industries ranging from power electronics to medical devices, where reliability and efficiency are paramount. As the demand for advanced electronic systems grows, so does the complexity of procuring the necessary components, including pulse capacitors. This blog post will explore the latest trends in pulse capacitors and the evolving procurement models that support their acquisition.

II. Understanding Pulse Capacitors

A. Types of Pulse Capacitors

Pulse capacitors come in several types, each with unique characteristics suited for specific applications:

1. **Film Capacitors**: Known for their stability and low ESR, film capacitors are widely used in power electronics and RF applications. They can handle high voltage and current levels, making them ideal for pulse applications.

2. **Ceramic Capacitors**: These capacitors are compact and offer high capacitance values in small packages. They are commonly used in RF applications and are known for their reliability and performance.

3. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in medical devices and automotive systems where space is limited, and reliability is critical.

B. Key Characteristics and Specifications

When selecting pulse capacitors, several key specifications must be considered:

1. **Voltage Rating**: The maximum voltage a capacitor can handle without failure. It is crucial to choose a capacitor with a voltage rating that exceeds the application's requirements.

2. **Capacitance Value**: This indicates the capacitor's ability to store charge. The required capacitance value will depend on the specific application and its energy storage needs.

3. **Equivalent Series Resistance (ESR)**: A measure of the resistance encountered by the current flowing through the capacitor. Lower ESR values are preferred for high-frequency applications to minimize energy loss.

4. **Ripple Current Handling**: The ability of a capacitor to handle AC currents superimposed on the DC voltage. This is particularly important in power electronics where pulsed signals are common.

C. Applications of Pulse Capacitors

Pulse capacitors find applications in various fields:

1. **Power Electronics**: Used in inverters, converters, and power supplies to manage energy storage and delivery efficiently.

2. **RF Applications**: Essential in communication devices, pulse capacitors help maintain signal integrity and performance.

3. **Medical Devices**: In devices like defibrillators and imaging equipment, pulse capacitors ensure reliable operation under critical conditions.

4. **Automotive Systems**: Used in electric vehicles and advanced driver-assistance systems (ADAS), pulse capacitors contribute to the performance and safety of modern vehicles.

III. Evolution of Procurement Models

A. Traditional Procurement Models

Historically, procurement models in the electronics industry have been straightforward:

1. **Direct Purchasing**: Companies would purchase components directly from manufacturers or distributors, often in bulk to secure lower prices.

2. **Bulk Buying**: This model involves purchasing large quantities of components to reduce costs, but it can lead to excess inventory and increased holding costs.

B. Shift Towards Modern Procurement Strategies

The landscape of procurement is evolving, with companies adopting more sophisticated strategies:

1. **Just-in-Time (JIT) Procurement**: This model minimizes inventory costs by ordering components only as needed. JIT helps companies respond quickly to market demands but requires a reliable supply chain.

2. **Vendor-Managed Inventory (VMI)**: In this model, suppliers manage the inventory levels of their products at the buyer's location. This approach can enhance efficiency and reduce stockouts.

3. **E-Procurement Systems**: Digital platforms streamline the procurement process, allowing companies to manage orders, track inventory, and analyze spending more effectively.

IV. Latest Trends in Pulse Capacitor Procurement

A. Increased Focus on Sustainability

As environmental concerns grow, the electronics industry is placing greater emphasis on sustainability:

1. **Eco-Friendly Materials**: Manufacturers are exploring the use of biodegradable and recyclable materials in capacitor production to reduce environmental impact.

2. **Lifecycle Assessment**: Companies are increasingly evaluating the environmental impact of components throughout their lifecycle, from production to disposal.

B. Digital Transformation in Procurement

The integration of technology is reshaping procurement processes:

1. **Use of AI and Machine Learning**: These technologies help companies analyze data, predict demand, and optimize supplier selection, leading to more informed procurement decisions.

2. **Blockchain for Supply Chain Transparency**: Blockchain technology enhances traceability and transparency in the supply chain, helping to ensure the authenticity and quality of components.

C. Collaborative Procurement Models

Collaboration is becoming a key strategy in procurement:

1. **Strategic Partnerships with Suppliers**: Companies are forming long-term relationships with suppliers to ensure a reliable supply of high-quality components.

2. **Consortium Buying**: By pooling resources with other companies, organizations can negotiate better prices and terms for bulk purchases of pulse capacitors.

V. Challenges in Pulse Capacitor Procurement

Despite advancements, several challenges persist in the procurement of pulse capacitors:

A. Supply Chain Disruptions

1. **Global Semiconductor Shortages**: The ongoing semiconductor shortage has affected the availability of many electronic components, including pulse capacitors.

2. **Geopolitical Factors**: Trade tensions and geopolitical instability can disrupt supply chains, leading to delays and increased costs.

B. Quality Assurance and Testing

1. **Ensuring Reliability and Performance**: As applications become more demanding, ensuring the quality and reliability of pulse capacitors is critical.

2. **Compliance with Industry Standards**: Manufacturers must adhere to strict industry standards, which can complicate the procurement process.

C. Cost Management

1. **Balancing Quality and Price**: Companies must navigate the trade-off between cost and quality, ensuring they procure reliable components without overspending.

2. **Long-Term vs. Short-Term Procurement Strategies**: Organizations must decide whether to invest in long-term contracts for stability or adopt flexible strategies to respond to market fluctuations.

VI. Case Studies

A. Successful Implementation of Modern Procurement Models

1. **Company A: Adopting JIT for Pulse Capacitors**: By implementing a JIT procurement strategy, Company A reduced inventory costs and improved responsiveness to market changes, leading to increased customer satisfaction.

2. **Company B: Leveraging AI for Supplier Selection**: Company B utilized AI algorithms to analyze supplier performance data, resulting in more informed decisions and improved supplier relationships.

B. Lessons Learned from Procurement Failures

1. **Company C: Challenges Faced During a Supply Chain Crisis**: Company C experienced significant delays and increased costs due to a lack of diversification in its supplier base, highlighting the importance of risk management in procurement.

VII. Future Outlook

A. Predictions for Pulse Capacitor Technology Advancements

As technology continues to evolve, we can expect advancements in pulse capacitor design, including higher capacitance values, improved energy density, and enhanced thermal performance.

B. Anticipated Changes in Procurement Models

The procurement landscape will likely continue to shift towards more collaborative and technology-driven approaches, with an emphasis on sustainability and supply chain resilience.

C. The Role of Innovation in Shaping Future Procurement Strategies

Innovation will play a crucial role in developing new procurement strategies, enabling companies to adapt to changing market conditions and consumer demands.

VIII. Conclusion

Pulse capacitors are vital components in modern electronics, and understanding the latest procurement models is essential for organizations looking to stay competitive. As the industry evolves, stakeholders must adapt to new trends and technologies to ensure efficient and sustainable procurement practices. By embracing innovation and collaboration, companies can navigate the challenges of the procurement landscape and secure the components necessary for their success.