Shandong Resistor Product Training Precautions

I. Introduction

A. Overview of Shandong Resistor Products

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Shandong, a province in China known for its robust manufacturing capabilities, produces a wide range of resistor products that are integral to various electronic applications. These resistors are not only vital components in consumer electronics but also find their place in industrial equipment and automotive applications. The demand for high-quality resistors continues to grow, making it essential for manufacturers and stakeholders to understand the intricacies of these products.

B. Purpose of the Training

The primary purpose of this training is to educate staff and stakeholders about Shandong resistor products. By providing comprehensive knowledge about these components, we aim to ensure product quality and safety. Understanding the specifications, applications, and handling precautions associated with resistors will empower employees to make informed decisions, ultimately leading to enhanced product reliability and customer satisfaction.

II. Understanding Resistor Basics

A. Definition and Function of Resistors

Resistors are passive electrical components that limit the flow of electric current in a circuit. They are essential for controlling voltage levels, dividing voltages, and protecting sensitive components from excessive current. Resistors come in various types, including fixed resistors, which have a constant resistance value, and variable resistors, which allow for adjustable resistance.

B. Key Specifications

When dealing with resistors, several key specifications must be understood:

1. **Resistance Value**: Measured in ohms (Ω), this value indicates how much the resistor opposes the flow of current.

2. **Power Rating**: This specification, measured in watts (W), indicates the maximum power the resistor can dissipate without being damaged.

3. **Tolerance**: This percentage indicates how much the actual resistance can vary from the stated value, which is crucial for precision applications.

4. **Temperature Coefficient**: This specification indicates how much the resistance changes with temperature, which is vital for applications in varying environmental conditions.

III. Shandong Resistor Product Range

A. Overview of Product Types

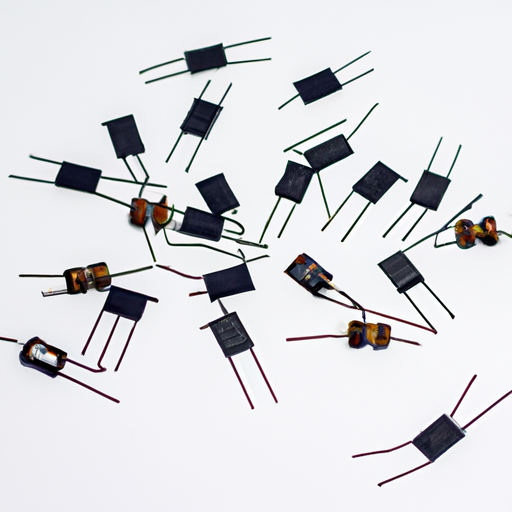

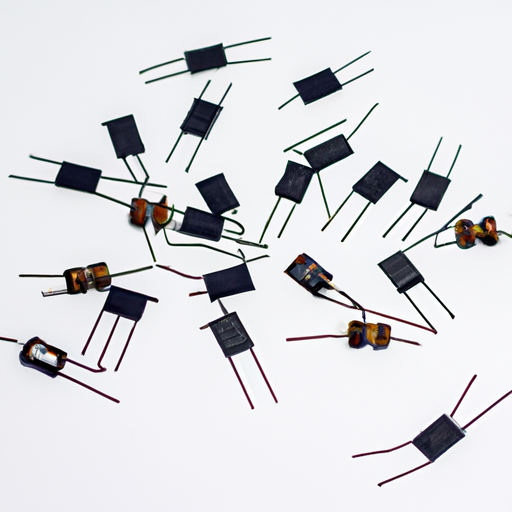

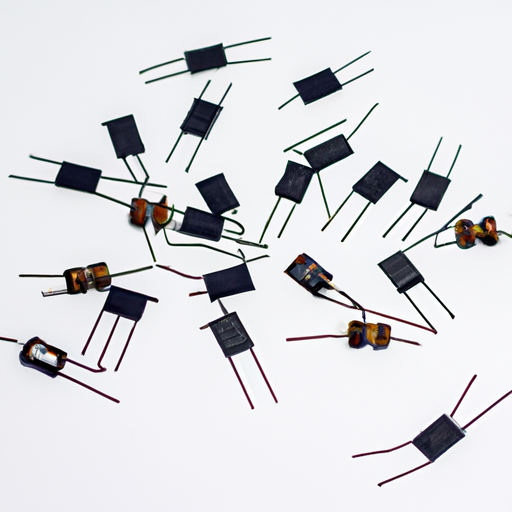

Shandong manufacturers offer a diverse range of resistor types, each designed for specific applications:

1. **Carbon Film Resistors**: Known for their stability and low cost, these resistors are commonly used in general-purpose applications.

2. **Metal Film Resistors**: These resistors provide higher precision and stability, making them suitable for more demanding applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic core, these resistors are ideal for high-power applications.

4. **Specialty Resistors**: This category includes a variety of resistors designed for specific applications, such as thermistors and photoresistors.

B. Applications of Shandong Resistors

Shandong resistors are utilized in various sectors, including:

1. **Consumer Electronics**: From televisions to smartphones, resistors are integral to the functionality of everyday devices.

2. **Industrial Equipment**: Resistors are used in machinery and control systems, ensuring reliable operation in demanding environments.

3. **Automotive Applications**: In vehicles, resistors play a role in electronic control units, sensors, and safety systems.

IV. Training Precautions

A. Safety Precautions

Safety is paramount when handling electronic components. Here are some essential safety precautions:

1. **Personal Protective Equipment (PPE)**: Employees should wear appropriate PPE, including gloves and safety glasses, to protect against potential hazards.

2. **Handling and Storage Guidelines**: Resistors should be handled with care to avoid damage. Proper storage conditions, such as controlled temperature and humidity, should be maintained to ensure product integrity.

B. Quality Control Measures

To maintain high standards of product quality, the following quality control measures should be implemented:

1. **Inspection Protocols**: Regular inspections should be conducted to ensure that resistors meet specified standards and are free from defects.

2. **Testing Procedures**: Comprehensive testing, including electrical testing and environmental testing, should be performed to verify the performance of resistors under various conditions.

C. Environmental Considerations

Compliance with environmental regulations is crucial in the manufacturing process. Companies should adopt waste management practices that minimize environmental impact and ensure proper disposal of electronic waste.

V. Technical Training Components

A. Understanding Product Specifications

A thorough understanding of product specifications is essential for effective training. Employees should be trained to:

1. **Read Datasheets**: Datasheets provide critical information about resistor specifications, including resistance values, power ratings, and tolerances.

2. **Interpret Technical Drawings**: Understanding technical drawings is vital for proper installation and application of resistors.

B. Installation and Usage Guidelines

Proper installation techniques are crucial for ensuring the longevity and performance of resistors. Training should cover:

1. **Proper Installation Techniques**: Employees should be trained on how to install resistors correctly to avoid damage and ensure optimal performance.

2. **Common Pitfalls to Avoid**: Awareness of common mistakes, such as incorrect soldering or exceeding power ratings, can prevent costly errors.

C. Troubleshooting and Maintenance

Training should also include troubleshooting and maintenance best practices:

1. **Identifying Common Issues**: Employees should be trained to recognize common problems, such as overheating or resistance drift, and understand their causes.

2. **Maintenance Best Practices**: Regular maintenance checks can help identify potential issues before they escalate, ensuring the reliability of resistor applications.

VI. Best Practices for Effective Training

A. Engaging Training Methods

To ensure effective training, engaging methods should be employed:

1. **Interactive Workshops**: Hands-on workshops allow employees to practice their skills in a controlled environment, enhancing their understanding of resistor applications.

2. **Hands-on Demonstrations**: Demonstrating installation and testing procedures can provide valuable insights and reinforce learning.

B. Continuous Learning and Development

The field of electronics is constantly evolving, making ongoing education essential:

1. **Importance of Ongoing Education**: Employees should be encouraged to pursue further education and training to stay updated on industry trends and advancements.

2. **Resources for Further Learning**: Providing access to online courses, webinars, and industry publications can support continuous learning.

VII. Conclusion

A. Recap of Key Points

In summary, understanding Shandong resistor products is essential for ensuring quality and safety in electronic applications. By familiarizing employees with resistor basics, product specifications, and handling precautions, organizations can enhance their operational efficiency.

B. Importance of Adhering to Training Precautions

Adhering to training precautions is vital for maintaining product integrity and ensuring the safety of employees. By implementing comprehensive training programs, companies can foster a culture of safety and quality.

C. Encouragement for a Culture of Safety and Quality

Encouraging a culture of safety and quality within the organization will not only improve product reliability but also enhance employee morale and customer satisfaction. By prioritizing training and education, companies can position themselves as leaders in the resistor manufacturing industry.

VIII. References

A. Suggested Reading Materials

1. "The Art of Electronics" by Paul Horowitz and Winfield Hill

2. "Electronic Components: A Complete Reference for Project Builders" by Mark J. Smith

B. Relevant Industry Standards and Guidelines

1. International Electrotechnical Commission (IEC) standards

2. American National Standards Institute (ANSI) guidelines

By following these guidelines and precautions, organizations can ensure that their training programs for Shandong resistor products are effective, informative, and conducive to a safe working environment.

Shandong Resistor Product Training Precautions

I. Introduction

A. Overview of Shandong Resistor Products

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Shandong, a province in China known for its robust manufacturing capabilities, produces a wide range of resistor products that are integral to various electronic applications. These resistors are not only vital components in consumer electronics but also find their place in industrial equipment and automotive applications. The demand for high-quality resistors continues to grow, making it essential for manufacturers and stakeholders to understand the intricacies of these products.

B. Purpose of the Training

The primary purpose of this training is to educate staff and stakeholders about Shandong resistor products. By providing comprehensive knowledge about these components, we aim to ensure product quality and safety. Understanding the specifications, applications, and handling precautions associated with resistors will empower employees to make informed decisions, ultimately leading to enhanced product reliability and customer satisfaction.

II. Understanding Resistor Basics

A. Definition and Function of Resistors

Resistors are passive electrical components that limit the flow of electric current in a circuit. They are essential for controlling voltage levels, dividing voltages, and protecting sensitive components from excessive current. Resistors come in various types, including fixed resistors, which have a constant resistance value, and variable resistors, which allow for adjustable resistance.

B. Key Specifications

When dealing with resistors, several key specifications must be understood:

1. **Resistance Value**: Measured in ohms (Ω), this value indicates how much the resistor opposes the flow of current.

2. **Power Rating**: This specification, measured in watts (W), indicates the maximum power the resistor can dissipate without being damaged.

3. **Tolerance**: This percentage indicates how much the actual resistance can vary from the stated value, which is crucial for precision applications.

4. **Temperature Coefficient**: This specification indicates how much the resistance changes with temperature, which is vital for applications in varying environmental conditions.

III. Shandong Resistor Product Range

A. Overview of Product Types

Shandong manufacturers offer a diverse range of resistor types, each designed for specific applications:

1. **Carbon Film Resistors**: Known for their stability and low cost, these resistors are commonly used in general-purpose applications.

2. **Metal Film Resistors**: These resistors provide higher precision and stability, making them suitable for more demanding applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic core, these resistors are ideal for high-power applications.

4. **Specialty Resistors**: This category includes a variety of resistors designed for specific applications, such as thermistors and photoresistors.

B. Applications of Shandong Resistors

Shandong resistors are utilized in various sectors, including:

1. **Consumer Electronics**: From televisions to smartphones, resistors are integral to the functionality of everyday devices.

2. **Industrial Equipment**: Resistors are used in machinery and control systems, ensuring reliable operation in demanding environments.

3. **Automotive Applications**: In vehicles, resistors play a role in electronic control units, sensors, and safety systems.

IV. Training Precautions

A. Safety Precautions

Safety is paramount when handling electronic components. Here are some essential safety precautions:

1. **Personal Protective Equipment (PPE)**: Employees should wear appropriate PPE, including gloves and safety glasses, to protect against potential hazards.

2. **Handling and Storage Guidelines**: Resistors should be handled with care to avoid damage. Proper storage conditions, such as controlled temperature and humidity, should be maintained to ensure product integrity.

B. Quality Control Measures

To maintain high standards of product quality, the following quality control measures should be implemented:

1. **Inspection Protocols**: Regular inspections should be conducted to ensure that resistors meet specified standards and are free from defects.

2. **Testing Procedures**: Comprehensive testing, including electrical testing and environmental testing, should be performed to verify the performance of resistors under various conditions.

C. Environmental Considerations

Compliance with environmental regulations is crucial in the manufacturing process. Companies should adopt waste management practices that minimize environmental impact and ensure proper disposal of electronic waste.

V. Technical Training Components

A. Understanding Product Specifications

A thorough understanding of product specifications is essential for effective training. Employees should be trained to:

1. **Read Datasheets**: Datasheets provide critical information about resistor specifications, including resistance values, power ratings, and tolerances.

2. **Interpret Technical Drawings**: Understanding technical drawings is vital for proper installation and application of resistors.

B. Installation and Usage Guidelines

Proper installation techniques are crucial for ensuring the longevity and performance of resistors. Training should cover:

1. **Proper Installation Techniques**: Employees should be trained on how to install resistors correctly to avoid damage and ensure optimal performance.

2. **Common Pitfalls to Avoid**: Awareness of common mistakes, such as incorrect soldering or exceeding power ratings, can prevent costly errors.

C. Troubleshooting and Maintenance

Training should also include troubleshooting and maintenance best practices:

1. **Identifying Common Issues**: Employees should be trained to recognize common problems, such as overheating or resistance drift, and understand their causes.

2. **Maintenance Best Practices**: Regular maintenance checks can help identify potential issues before they escalate, ensuring the reliability of resistor applications.

VI. Best Practices for Effective Training

A. Engaging Training Methods

To ensure effective training, engaging methods should be employed:

1. **Interactive Workshops**: Hands-on workshops allow employees to practice their skills in a controlled environment, enhancing their understanding of resistor applications.

2. **Hands-on Demonstrations**: Demonstrating installation and testing procedures can provide valuable insights and reinforce learning.

B. Continuous Learning and Development

The field of electronics is constantly evolving, making ongoing education essential:

1. **Importance of Ongoing Education**: Employees should be encouraged to pursue further education and training to stay updated on industry trends and advancements.

2. **Resources for Further Learning**: Providing access to online courses, webinars, and industry publications can support continuous learning.

VII. Conclusion

A. Recap of Key Points

In summary, understanding Shandong resistor products is essential for ensuring quality and safety in electronic applications. By familiarizing employees with resistor basics, product specifications, and handling precautions, organizations can enhance their operational efficiency.

B. Importance of Adhering to Training Precautions

Adhering to training precautions is vital for maintaining product integrity and ensuring the safety of employees. By implementing comprehensive training programs, companies can foster a culture of safety and quality.

C. Encouragement for a Culture of Safety and Quality

Encouraging a culture of safety and quality within the organization will not only improve product reliability but also enhance employee morale and customer satisfaction. By prioritizing training and education, companies can position themselves as leaders in the resistor manufacturing industry.

VIII. References

A. Suggested Reading Materials

1. "The Art of Electronics" by Paul Horowitz and Winfield Hill

2. "Electronic Components: A Complete Reference for Project Builders" by Mark J. Smith

B. Relevant Industry Standards and Guidelines

1. International Electrotechnical Commission (IEC) standards

2. American National Standards Institute (ANSI) guidelines

By following these guidelines and precautions, organizations can ensure that their training programs for Shandong resistor products are effective, informative, and conducive to a safe working environment.