What are the Product Features of Braking Resistors?

I. Introduction

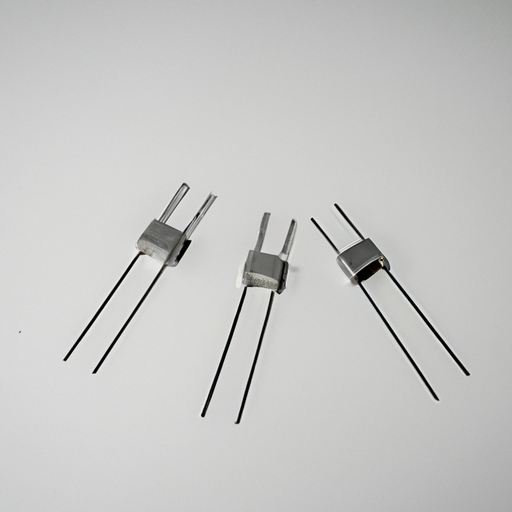

Braking resistors are essential components in various electrical systems, designed to manage and dissipate energy during braking processes. They play a crucial role in ensuring the safety and efficiency of machinery, electric vehicles, and renewable energy systems. This article aims to explore the product features of braking resistors, providing insights into their functionality, types, key characteristics, and applications.

II. Understanding Braking Resistors

A. Basic Principles of Braking Resistors

Braking resistors function by converting kinetic energy into heat during the braking process. When a motor or system decelerates, the energy generated must be dissipated to prevent damage to the system. Braking resistors absorb this excess energy, allowing for smoother and safer operation.

B. Types of Braking Resistors

1. **Dynamic Braking Resistors**: These resistors are used in dynamic braking systems, where the motor acts as a generator during deceleration. The generated energy is routed to the braking resistor, where it is dissipated as heat.

2. **Regenerative Braking Resistors**: In regenerative braking systems, the energy generated during braking is fed back into the power supply or battery. While these systems may not always require a braking resistor, they can be used to manage excess energy.

3. **Other Specialized Types**: There are various specialized braking resistors designed for specific applications, such as those used in high-power industrial machinery or renewable energy systems.

III. Key Product Features of Braking Resistors

A. Power Rating

The power rating of a braking resistor indicates its ability to handle energy dissipation without overheating. It is crucial to select a resistor with an appropriate power rating based on the application’s requirements. Factors such as the duration and frequency of braking events will influence the necessary power rating.

B. Resistance Value

The resistance value of a braking resistor affects its performance and efficiency. A higher resistance value will result in greater energy dissipation but may also lead to increased heat generation. Conversely, a lower resistance value may allow for quicker energy dissipation but could compromise braking effectiveness. Understanding the specific needs of the application is essential for selecting the right resistance value.

C. Thermal Management

Effective thermal management is vital for the longevity and reliability of braking resistors. As they dissipate energy, they generate heat, which must be managed to prevent damage. Common cooling methods include:

Air-Cooled: Utilizing airflow to dissipate heat, suitable for applications with lower power ratings.

Water-Cooled: Employing water circulation for cooling, ideal for high-power applications where heat generation is significant.

D. Construction Materials

The materials used in the construction of braking resistors significantly impact their durability and performance. Common materials include:

Wire Wound: Known for their high power ratings and reliability, wire-wound resistors are often used in dynamic braking applications.

Ceramic: Ceramic resistors offer excellent thermal stability and are suitable for high-temperature environments.

E. Size and Form Factor

The size and form factor of braking resistors are crucial considerations, especially in applications with limited installation space. Compact designs can facilitate easier integration into existing systems without compromising performance.

F. Voltage Rating

The voltage rating of a braking resistor indicates the maximum voltage it can handle. It is essential to match the voltage rating to the system requirements to prevent failure or damage. Selecting a resistor with an appropriate voltage rating ensures safe and efficient operation.

G. Safety Features

Safety is paramount in braking resistor design. Key safety features include:

Over-Temperature Protection: Prevents overheating by shutting down the resistor or diverting energy when temperatures exceed safe limits.

Short-Circuit Protection: Safeguards against electrical faults that could damage the resistor or connected systems.

Insulation and Grounding Considerations: Proper insulation and grounding are essential to prevent electrical hazards and ensure safe operation.

IV. Performance Characteristics

A. Response Time

In braking applications, quick response time is critical. The ability of a braking resistor to react promptly to changes in energy levels can significantly impact the overall performance of the system. Factors such as the design and materials used can influence response time.

B. Efficiency

Efficiency in braking systems refers to the effective conversion and dissipation of energy. Braking resistors contribute to overall system efficiency by ensuring that excess energy is managed effectively, reducing waste and improving performance.

C. Reliability and Longevity

The lifespan of braking resistors is influenced by various factors, including thermal management, construction materials, and operating conditions. Reliable braking resistors are essential in critical applications, where failure could lead to safety hazards or operational downtime.

V. Applications of Braking Resistors

A. Industrial Machinery

Braking resistors are widely used in industrial machinery, including cranes, elevators, and conveyors. They ensure safe and efficient operation by managing energy during braking events, preventing mechanical wear and tear.

B. Electric Vehicles

In electric vehicles, braking resistors play a vital role in regenerative braking systems. They help manage excess energy generated during braking, allowing for improved energy efficiency and extended battery life.

C. Renewable Energy Systems

Braking resistors are also utilized in renewable energy systems, such as wind turbines and solar inverters. They help manage energy fluctuations and ensure stable operation, contributing to the overall efficiency of these systems.

D. Other Applications

Braking resistors find applications in various other fields, including HVAC systems, robotics, and more. Their ability to manage energy dissipation makes them versatile components in many electrical systems.

VI. Selection Criteria for Braking Resistors

When selecting braking resistors, several criteria should be considered:

A. Assessing Application Requirements

Understanding the specific requirements of the application is crucial. Factors such as power rating, resistance value, and thermal management needs must be evaluated to ensure optimal performance.

B. Evaluating Manufacturer Specifications

Reviewing manufacturer specifications can provide valuable insights into the performance characteristics and reliability of braking resistors. It is essential to choose reputable manufacturers known for quality products.

C. Importance of Consulting with Experts

Consulting with experts in the field can help ensure that the right braking resistor is selected for the application. Their knowledge and experience can provide valuable guidance in navigating the complexities of braking resistor selection.

VII. Conclusion

Braking resistors are vital components in modern electrical systems, playing a crucial role in energy management and safety. Understanding their key product features, including power rating, resistance value, thermal management, and safety features, is essential for selecting the right resistor for specific applications. As technology continues to evolve, the importance of braking resistors in various industries will only grow, making them indispensable in ensuring efficient and safe operation.

VIII. References

For further information on braking resistors, consider exploring the following resources:

- Industry standards and guidelines related to braking resistors.

- Technical papers and articles on braking resistor technology.

- Manufacturer websites for product specifications and application notes.

By understanding the features and applications of braking resistors, engineers and technicians can make informed decisions that enhance the performance and safety of their systems.

What are the Product Features of Braking Resistors?

I. Introduction

Braking resistors are essential components in various electrical systems, designed to manage and dissipate energy during braking processes. They play a crucial role in ensuring the safety and efficiency of machinery, electric vehicles, and renewable energy systems. This article aims to explore the product features of braking resistors, providing insights into their functionality, types, key characteristics, and applications.

II. Understanding Braking Resistors

A. Basic Principles of Braking Resistors

Braking resistors function by converting kinetic energy into heat during the braking process. When a motor or system decelerates, the energy generated must be dissipated to prevent damage to the system. Braking resistors absorb this excess energy, allowing for smoother and safer operation.

B. Types of Braking Resistors

1. **Dynamic Braking Resistors**: These resistors are used in dynamic braking systems, where the motor acts as a generator during deceleration. The generated energy is routed to the braking resistor, where it is dissipated as heat.

2. **Regenerative Braking Resistors**: In regenerative braking systems, the energy generated during braking is fed back into the power supply or battery. While these systems may not always require a braking resistor, they can be used to manage excess energy.

3. **Other Specialized Types**: There are various specialized braking resistors designed for specific applications, such as those used in high-power industrial machinery or renewable energy systems.

III. Key Product Features of Braking Resistors

A. Power Rating

The power rating of a braking resistor indicates its ability to handle energy dissipation without overheating. It is crucial to select a resistor with an appropriate power rating based on the application’s requirements. Factors such as the duration and frequency of braking events will influence the necessary power rating.

B. Resistance Value

The resistance value of a braking resistor affects its performance and efficiency. A higher resistance value will result in greater energy dissipation but may also lead to increased heat generation. Conversely, a lower resistance value may allow for quicker energy dissipation but could compromise braking effectiveness. Understanding the specific needs of the application is essential for selecting the right resistance value.

C. Thermal Management

Effective thermal management is vital for the longevity and reliability of braking resistors. As they dissipate energy, they generate heat, which must be managed to prevent damage. Common cooling methods include:

Air-Cooled: Utilizing airflow to dissipate heat, suitable for applications with lower power ratings.

Water-Cooled: Employing water circulation for cooling, ideal for high-power applications where heat generation is significant.

D. Construction Materials

The materials used in the construction of braking resistors significantly impact their durability and performance. Common materials include:

Wire Wound: Known for their high power ratings and reliability, wire-wound resistors are often used in dynamic braking applications.

Ceramic: Ceramic resistors offer excellent thermal stability and are suitable for high-temperature environments.

E. Size and Form Factor

The size and form factor of braking resistors are crucial considerations, especially in applications with limited installation space. Compact designs can facilitate easier integration into existing systems without compromising performance.

F. Voltage Rating

The voltage rating of a braking resistor indicates the maximum voltage it can handle. It is essential to match the voltage rating to the system requirements to prevent failure or damage. Selecting a resistor with an appropriate voltage rating ensures safe and efficient operation.

G. Safety Features

Safety is paramount in braking resistor design. Key safety features include:

Over-Temperature Protection: Prevents overheating by shutting down the resistor or diverting energy when temperatures exceed safe limits.

Short-Circuit Protection: Safeguards against electrical faults that could damage the resistor or connected systems.

Insulation and Grounding Considerations: Proper insulation and grounding are essential to prevent electrical hazards and ensure safe operation.

IV. Performance Characteristics

A. Response Time

In braking applications, quick response time is critical. The ability of a braking resistor to react promptly to changes in energy levels can significantly impact the overall performance of the system. Factors such as the design and materials used can influence response time.

B. Efficiency

Efficiency in braking systems refers to the effective conversion and dissipation of energy. Braking resistors contribute to overall system efficiency by ensuring that excess energy is managed effectively, reducing waste and improving performance.

C. Reliability and Longevity

The lifespan of braking resistors is influenced by various factors, including thermal management, construction materials, and operating conditions. Reliable braking resistors are essential in critical applications, where failure could lead to safety hazards or operational downtime.

V. Applications of Braking Resistors

A. Industrial Machinery

Braking resistors are widely used in industrial machinery, including cranes, elevators, and conveyors. They ensure safe and efficient operation by managing energy during braking events, preventing mechanical wear and tear.

B. Electric Vehicles

In electric vehicles, braking resistors play a vital role in regenerative braking systems. They help manage excess energy generated during braking, allowing for improved energy efficiency and extended battery life.

C. Renewable Energy Systems

Braking resistors are also utilized in renewable energy systems, such as wind turbines and solar inverters. They help manage energy fluctuations and ensure stable operation, contributing to the overall efficiency of these systems.

D. Other Applications

Braking resistors find applications in various other fields, including HVAC systems, robotics, and more. Their ability to manage energy dissipation makes them versatile components in many electrical systems.

VI. Selection Criteria for Braking Resistors

When selecting braking resistors, several criteria should be considered:

A. Assessing Application Requirements

Understanding the specific requirements of the application is crucial. Factors such as power rating, resistance value, and thermal management needs must be evaluated to ensure optimal performance.

B. Evaluating Manufacturer Specifications

Reviewing manufacturer specifications can provide valuable insights into the performance characteristics and reliability of braking resistors. It is essential to choose reputable manufacturers known for quality products.

C. Importance of Consulting with Experts

Consulting with experts in the field can help ensure that the right braking resistor is selected for the application. Their knowledge and experience can provide valuable guidance in navigating the complexities of braking resistor selection.

VII. Conclusion

Braking resistors are vital components in modern electrical systems, playing a crucial role in energy management and safety. Understanding their key product features, including power rating, resistance value, thermal management, and safety features, is essential for selecting the right resistor for specific applications. As technology continues to evolve, the importance of braking resistors in various industries will only grow, making them indispensable in ensuring efficient and safe operation.

VIII. References

For further information on braking resistors, consider exploring the following resources:

- Industry standards and guidelines related to braking resistors.

- Technical papers and articles on braking resistor technology.

- Manufacturer websites for product specifications and application notes.

By understanding the features and applications of braking resistors, engineers and technicians can make informed decisions that enhance the performance and safety of their systems.