What is a Film Capacitor?

I. Introduction

In the world of electronics, capacitors play a crucial role in the functionality and performance of circuits. Among the various types of capacitors, film capacitors stand out due to their unique properties and applications. This article will delve into what film capacitors are, their construction, advantages, disadvantages, and their role in modern electronic design. By the end, readers will have a comprehensive understanding of film capacitors and their significance in electronic circuits.

II. Basic Principles of Capacitors

A. Definition and Function of Capacitors

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are essential for various functions, including filtering, timing, and energy storage.

B. Types of Capacitors

Capacitors come in various types, each with distinct characteristics and applications. The most common types include:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte as one of the plates. They are polarized, meaning they must be connected in a specific direction in a circuit.

2. **Ceramic Capacitors**: These capacitors use ceramic materials as the dielectric. They are non-polarized and are often used in high-frequency applications due to their low equivalent series resistance (ESR).

3. **Film Capacitors**: These capacitors use thin plastic films as the dielectric. They are known for their stability and reliability, making them suitable for various applications.

C. Key Characteristics of Capacitors

When evaluating capacitors, several key characteristics are essential:

1. **Capacitance**: Measured in farads (F), capacitance indicates the amount of charge a capacitor can store.

2. **Voltage Rating**: This is the maximum voltage a capacitor can handle without breaking down.

3. **Equivalent Series Resistance (ESR)**: This parameter measures the internal resistance of the capacitor, affecting its efficiency and performance in circuits.

III. What is a Film Capacitor?

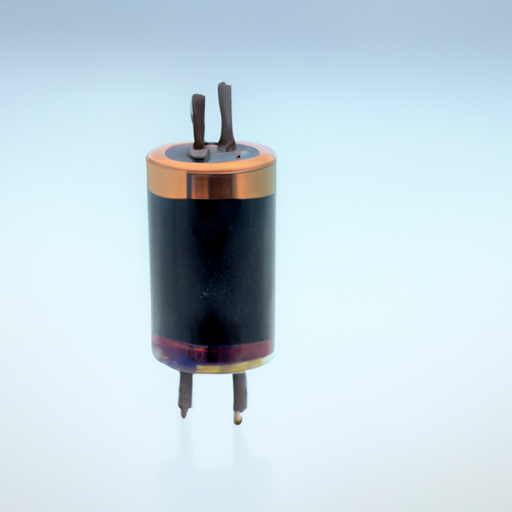

A. Composition and Construction

Film capacitors are constructed using thin plastic films as the dielectric material. The most common dielectric materials include:

1. **Polyester**: Known for its good electrical properties and cost-effectiveness.

2. **Polypropylene**: Offers excellent stability and low losses, making it ideal for high-frequency applications.

3. **Polycarbonate**: Provides high capacitance stability over a wide temperature range.

B. Manufacturing Process

The manufacturing process of film capacitors involves several steps:

1. **Film Production**: The dielectric film is produced by extruding or casting the plastic material into thin sheets.

2. **Layering and Winding Techniques**: The dielectric film is layered with conductive materials (usually metal) and then wound into a cylindrical shape or stacked, depending on the design.

C. Physical Characteristics

Film capacitors come in various sizes and shapes, typically cylindrical or rectangular. They can also have different termination options, such as leads for through-hole mounting or surface-mount technology (SMT) pads for modern circuit boards.

IV. Advantages of Film Capacitors

Film capacitors offer several advantages that make them a popular choice in many applications:

A. Stability and Reliability

Film capacitors are known for their excellent stability over time and temperature. They exhibit minimal capacitance drift, making them reliable for precision applications.

B. Low ESR and ESL

Film capacitors have low equivalent series resistance (ESR) and equivalent series inductance (ESL), which enhances their performance in high-frequency applications. This characteristic reduces energy losses and improves efficiency.

C. Wide Temperature Range

Film capacitors can operate effectively over a wide temperature range, typically from -40°C to +85°C or even higher, depending on the dielectric material used.

D. Long Lifespan

With a long operational life, film capacitors can last for decades, making them a cost-effective choice in the long run.

E. Low Self-Heating

Due to their low ESR, film capacitors generate less heat during operation, which contributes to their longevity and reliability.

V. Disadvantages of Film Capacitors

Despite their advantages, film capacitors also have some drawbacks:

A. Size and Weight Considerations

Film capacitors tend to be larger and heavier than other types, such as ceramic capacitors. This can be a disadvantage in applications where space and weight are critical.

B. Cost Compared to Other Capacitor Types

Film capacitors are generally more expensive than electrolytic and ceramic capacitors, which can be a limiting factor in cost-sensitive applications.

C. Limited Capacitance Values

While film capacitors are available in various capacitance values, they typically do not reach the high capacitance levels of electrolytic capacitors, which can limit their use in certain applications.

VI. Applications of Film Capacitors

Film capacitors are widely used in various applications due to their unique properties:

A. Audio Equipment

In audio applications, film capacitors are favored for their low distortion and high fidelity, making them ideal for coupling and bypassing in audio circuits.

B. Power Electronics

Film capacitors are used in power electronics for filtering and energy storage, particularly in applications requiring high reliability and performance.

C. Signal Processing

In signal processing circuits, film capacitors help maintain signal integrity and reduce noise, making them essential for high-frequency applications.

D. Timing Circuits

Film capacitors are commonly used in timing circuits due to their stability and reliability, ensuring accurate timing in various electronic devices.

E. Renewable Energy Systems

In renewable energy systems, such as solar inverters and wind turbines, film capacitors are used for energy storage and filtering, contributing to the efficiency and reliability of these systems.

VII. Comparison with Other Capacitor Types

A. Film Capacitors vs. Electrolytic Capacitors

While electrolytic capacitors offer high capacitance values, they are polarized and can be less reliable in certain applications. Film capacitors, on the other hand, provide better stability and lower ESR, making them suitable for high-frequency and precision applications.

B. Film Capacitors vs. Ceramic Capacitors

Ceramic capacitors are smaller and less expensive but may have higher ESR and lower stability compared to film capacitors. Film capacitors excel in applications requiring low distortion and high reliability.

C. Performance Metrics and Use Cases

When comparing performance metrics, film capacitors often outperform electrolytic and ceramic capacitors in terms of stability, reliability, and low losses, making them the preferred choice in many high-performance applications.

VIII. Future Trends and Innovations

A. Advances in Materials and Technology

Ongoing research in materials science is leading to the development of new dielectric materials that enhance the performance of film capacitors, allowing for smaller sizes and higher capacitance values.

B. Emerging Applications in Modern Electronics

As technology advances, film capacitors are finding new applications in areas such as electric vehicles, renewable energy systems, and high-frequency communication devices.

C. Environmental Considerations and Sustainability

With increasing awareness of environmental issues, manufacturers are exploring sustainable materials and production methods for film capacitors, aiming to reduce their ecological footprint.

IX. Conclusion

Film capacitors are a vital component in modern electronic design, offering stability, reliability, and performance in various applications. Their unique properties make them suitable for high-frequency, precision, and power applications. As technology continues to evolve, film capacitors will play an increasingly important role in shaping the future of electronics. For those interested in exploring the world of capacitors further, understanding film capacitors is a crucial step in grasping the complexities of electronic design.

X. References

For further reading and resources on film capacitors, consider exploring the following:

1. "Capacitors: Technology and Applications" by John Smith

2. IEEE Standards for Capacitors

3. Manufacturer datasheets and application notes for specific film capacitor products

By understanding the significance of film capacitors, engineers and enthusiasts alike can make informed decisions in their electronic designs and applications.

What is a Film Capacitor?

I. Introduction

In the world of electronics, capacitors play a crucial role in the functionality and performance of circuits. Among the various types of capacitors, film capacitors stand out due to their unique properties and applications. This article will delve into what film capacitors are, their construction, advantages, disadvantages, and their role in modern electronic design. By the end, readers will have a comprehensive understanding of film capacitors and their significance in electronic circuits.

II. Basic Principles of Capacitors

A. Definition and Function of Capacitors

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are essential for various functions, including filtering, timing, and energy storage.

B. Types of Capacitors

Capacitors come in various types, each with distinct characteristics and applications. The most common types include:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte as one of the plates. They are polarized, meaning they must be connected in a specific direction in a circuit.

2. **Ceramic Capacitors**: These capacitors use ceramic materials as the dielectric. They are non-polarized and are often used in high-frequency applications due to their low equivalent series resistance (ESR).

3. **Film Capacitors**: These capacitors use thin plastic films as the dielectric. They are known for their stability and reliability, making them suitable for various applications.

C. Key Characteristics of Capacitors

When evaluating capacitors, several key characteristics are essential:

1. **Capacitance**: Measured in farads (F), capacitance indicates the amount of charge a capacitor can store.

2. **Voltage Rating**: This is the maximum voltage a capacitor can handle without breaking down.

3. **Equivalent Series Resistance (ESR)**: This parameter measures the internal resistance of the capacitor, affecting its efficiency and performance in circuits.

III. What is a Film Capacitor?

A. Composition and Construction

Film capacitors are constructed using thin plastic films as the dielectric material. The most common dielectric materials include:

1. **Polyester**: Known for its good electrical properties and cost-effectiveness.

2. **Polypropylene**: Offers excellent stability and low losses, making it ideal for high-frequency applications.

3. **Polycarbonate**: Provides high capacitance stability over a wide temperature range.

B. Manufacturing Process

The manufacturing process of film capacitors involves several steps:

1. **Film Production**: The dielectric film is produced by extruding or casting the plastic material into thin sheets.

2. **Layering and Winding Techniques**: The dielectric film is layered with conductive materials (usually metal) and then wound into a cylindrical shape or stacked, depending on the design.

C. Physical Characteristics

Film capacitors come in various sizes and shapes, typically cylindrical or rectangular. They can also have different termination options, such as leads for through-hole mounting or surface-mount technology (SMT) pads for modern circuit boards.

IV. Advantages of Film Capacitors

Film capacitors offer several advantages that make them a popular choice in many applications:

A. Stability and Reliability

Film capacitors are known for their excellent stability over time and temperature. They exhibit minimal capacitance drift, making them reliable for precision applications.

B. Low ESR and ESL

Film capacitors have low equivalent series resistance (ESR) and equivalent series inductance (ESL), which enhances their performance in high-frequency applications. This characteristic reduces energy losses and improves efficiency.

C. Wide Temperature Range

Film capacitors can operate effectively over a wide temperature range, typically from -40°C to +85°C or even higher, depending on the dielectric material used.

D. Long Lifespan

With a long operational life, film capacitors can last for decades, making them a cost-effective choice in the long run.

E. Low Self-Heating

Due to their low ESR, film capacitors generate less heat during operation, which contributes to their longevity and reliability.

V. Disadvantages of Film Capacitors

Despite their advantages, film capacitors also have some drawbacks:

A. Size and Weight Considerations

Film capacitors tend to be larger and heavier than other types, such as ceramic capacitors. This can be a disadvantage in applications where space and weight are critical.

B. Cost Compared to Other Capacitor Types

Film capacitors are generally more expensive than electrolytic and ceramic capacitors, which can be a limiting factor in cost-sensitive applications.

C. Limited Capacitance Values

While film capacitors are available in various capacitance values, they typically do not reach the high capacitance levels of electrolytic capacitors, which can limit their use in certain applications.

VI. Applications of Film Capacitors

Film capacitors are widely used in various applications due to their unique properties:

A. Audio Equipment

In audio applications, film capacitors are favored for their low distortion and high fidelity, making them ideal for coupling and bypassing in audio circuits.

B. Power Electronics

Film capacitors are used in power electronics for filtering and energy storage, particularly in applications requiring high reliability and performance.

C. Signal Processing

In signal processing circuits, film capacitors help maintain signal integrity and reduce noise, making them essential for high-frequency applications.

D. Timing Circuits

Film capacitors are commonly used in timing circuits due to their stability and reliability, ensuring accurate timing in various electronic devices.

E. Renewable Energy Systems

In renewable energy systems, such as solar inverters and wind turbines, film capacitors are used for energy storage and filtering, contributing to the efficiency and reliability of these systems.

VII. Comparison with Other Capacitor Types

A. Film Capacitors vs. Electrolytic Capacitors

While electrolytic capacitors offer high capacitance values, they are polarized and can be less reliable in certain applications. Film capacitors, on the other hand, provide better stability and lower ESR, making them suitable for high-frequency and precision applications.

B. Film Capacitors vs. Ceramic Capacitors

Ceramic capacitors are smaller and less expensive but may have higher ESR and lower stability compared to film capacitors. Film capacitors excel in applications requiring low distortion and high reliability.

C. Performance Metrics and Use Cases

When comparing performance metrics, film capacitors often outperform electrolytic and ceramic capacitors in terms of stability, reliability, and low losses, making them the preferred choice in many high-performance applications.

VIII. Future Trends and Innovations

A. Advances in Materials and Technology

Ongoing research in materials science is leading to the development of new dielectric materials that enhance the performance of film capacitors, allowing for smaller sizes and higher capacitance values.

B. Emerging Applications in Modern Electronics

As technology advances, film capacitors are finding new applications in areas such as electric vehicles, renewable energy systems, and high-frequency communication devices.

C. Environmental Considerations and Sustainability

With increasing awareness of environmental issues, manufacturers are exploring sustainable materials and production methods for film capacitors, aiming to reduce their ecological footprint.

IX. Conclusion

Film capacitors are a vital component in modern electronic design, offering stability, reliability, and performance in various applications. Their unique properties make them suitable for high-frequency, precision, and power applications. As technology continues to evolve, film capacitors will play an increasingly important role in shaping the future of electronics. For those interested in exploring the world of capacitors further, understanding film capacitors is a crucial step in grasping the complexities of electronic design.

X. References

For further reading and resources on film capacitors, consider exploring the following:

1. "Capacitors: Technology and Applications" by John Smith

2. IEEE Standards for Capacitors

3. Manufacturer datasheets and application notes for specific film capacitor products

By understanding the significance of film capacitors, engineers and enthusiasts alike can make informed decisions in their electronic designs and applications.