Product Features of Glass Glaze Resistors

I. Introduction

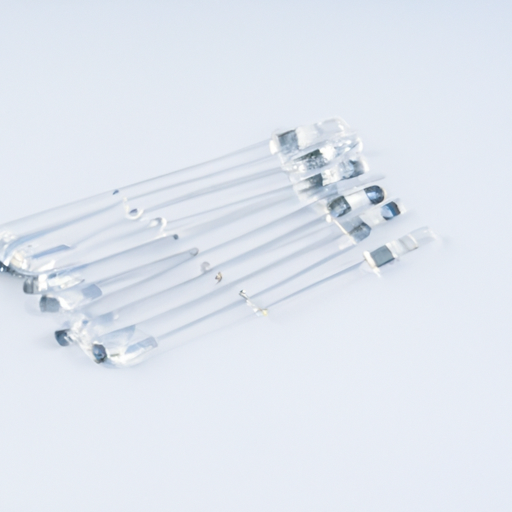

A. Definition of Glass Glaze Resistors

Glass glaze resistors are a type of passive electronic component that provides resistance to the flow of electric current. They are characterized by a unique glass glaze coating that enhances their performance and durability. These resistors are widely used in various electronic applications due to their ability to maintain stable resistance values under varying environmental conditions.

B. Importance of Resistors in Electronic Circuits

Resistors play a crucial role in electronic circuits by controlling the flow of current, dividing voltages, and protecting sensitive components from excessive current. They are essential for ensuring the proper functioning of electronic devices, making their reliability and performance critical to overall circuit design.

C. Overview of Glass Glaze Technology

The glass glaze technology used in these resistors involves applying a glass-like coating to a substrate, which not only provides electrical insulation but also enhances the mechanical and thermal properties of the resistor. This technology has led to the development of resistors that can withstand extreme conditions, making them suitable for a wide range of applications.

II. Composition and Construction

A. Materials Used in Glass Glaze Resistors

1. Glass Glaze Material

The primary component of glass glaze resistors is the glass glaze itself, which is a mixture of silica, alumina, and other oxides. This material is chosen for its excellent insulating properties and ability to withstand high temperatures.

2. Conductive Elements

The conductive elements in glass glaze resistors typically include metal oxides or carbon-based materials. These elements are carefully selected to achieve specific resistance values and ensure reliable performance.

B. Manufacturing Process

1. Application of Glass Glaze

The manufacturing process begins with the application of the glass glaze material onto a ceramic substrate. This is usually done through a screen printing or spraying technique, ensuring an even coating.

2. Firing Process

Once the glaze is applied, the resistors undergo a firing process in a kiln. This step is crucial as it causes the glass to melt and bond with the substrate, creating a solid and durable structure.

3. Final Assembly

After firing, the resistors are cooled and undergo final assembly, which may include adding leads or terminals for integration into electronic circuits. Quality control measures are implemented to ensure that each resistor meets specified performance standards.

III. Key Features of Glass Glaze Resistors

A. High Temperature Stability

1. Thermal Characteristics

Glass glaze resistors exhibit excellent thermal stability, allowing them to operate effectively in high-temperature environments. They can typically withstand temperatures up to 200°C or more without significant changes in resistance.

2. Applications in High-Temperature Environments

This thermal stability makes glass glaze resistors ideal for applications in automotive, aerospace, and industrial equipment, where exposure to extreme temperatures is common.

B. Excellent Electrical Performance

1. Resistance Values and Tolerances

These resistors are available in a wide range of resistance values, with tight tolerances that ensure consistent performance. This precision is essential for applications requiring accurate current control.

2. Voltage Ratings

Glass glaze resistors can handle high voltage levels, making them suitable for use in power electronics and other high-voltage applications.

C. Environmental Resistance

1. Moisture and Humidity Resistance

The glass glaze coating provides excellent moisture and humidity resistance, preventing corrosion and degradation over time. This feature is particularly important in outdoor and humid environments.

2. Chemical Resistance

Glass glaze resistors are also resistant to various chemicals, making them suitable for use in harsh industrial settings where exposure to corrosive substances may occur.

D. Mechanical Strength

1. Durability and Longevity

The robust construction of glass glaze resistors ensures high durability and longevity, reducing the need for frequent replacements and maintenance.

2. Resistance to Mechanical Stress

These resistors can withstand mechanical stress, such as vibrations and shocks, making them ideal for applications in automotive and aerospace industries.

E. Low Noise Characteristics

1. Importance of Low Noise in Circuits

Low noise is a critical factor in many electronic applications, particularly in audio and precision measurement devices. Glass glaze resistors are designed to minimize electrical noise, ensuring clean signal transmission.

2. Comparison with Other Resistor Types

When compared to other resistor types, such as carbon composition resistors, glass glaze resistors exhibit significantly lower noise levels, making them a preferred choice in sensitive applications.

IV. Advantages of Glass Glaze Resistors

A. Versatility in Applications

1. Use in Consumer Electronics

Glass glaze resistors are commonly used in consumer electronics, including televisions, computers, and audio equipment, where reliability and performance are paramount.

2. Industrial Applications

In industrial settings, these resistors are utilized in control systems, automation equipment, and power supplies, where their durability and environmental resistance are advantageous.

3. Automotive and Aerospace Industries

The automotive and aerospace industries benefit from the high-temperature stability and mechanical strength of glass glaze resistors, making them suitable for critical applications in vehicles and aircraft.

B. Cost-Effectiveness

1. Comparison with Other Resistor Types

While glass glaze resistors may have a higher initial cost compared to some alternatives, their durability and long lifespan often result in lower overall costs in the long run.

2. Long-Term Savings

The reduced need for replacements and maintenance contributes to long-term savings, making glass glaze resistors a cost-effective choice for many applications.

C. Customization Options

1. Tailored Resistance Values

Manufacturers can produce glass glaze resistors with specific resistance values tailored to meet the unique requirements of various applications.

2. Specific Size and Shape Configurations

Customization extends to size and shape, allowing designers to integrate these resistors seamlessly into their circuit designs.

V. Limitations of Glass Glaze Resistors

A. Potential Drawbacks

1. Size Constraints

One limitation of glass glaze resistors is their size. They may not be suitable for applications requiring very compact components, as their construction can be bulkier than other resistor types.

2. Limited Availability in Certain Markets

In some regions, glass glaze resistors may not be as readily available as other types, potentially limiting their use in specific applications.

B. Comparison with Alternative Resistor Technologies

1. Metal Film Resistors

Metal film resistors offer high precision and low noise but may not match the thermal stability and environmental resistance of glass glaze resistors.

2. Carbon Composition Resistors

While carbon composition resistors are cost-effective, they typically have higher noise levels and lower temperature stability compared to glass glaze resistors.

VI. Applications of Glass Glaze Resistors

A. Overview of Common Applications

Glass glaze resistors are utilized in a variety of applications, including consumer electronics, industrial equipment, automotive systems, and aerospace technology. Their unique features make them suitable for environments where reliability and performance are critical.

B. Case Studies

1. Consumer Electronics

In consumer electronics, glass glaze resistors are used in power supply circuits, audio amplifiers, and signal processing devices, where their low noise and stability enhance overall performance.

2. Industrial Equipment

In industrial equipment, these resistors are employed in control systems and automation devices, ensuring reliable operation in demanding environments.

3. Automotive Systems

In automotive systems, glass glaze resistors are used in engine control units and safety systems, where their high-temperature stability and mechanical strength are essential.

VII. Conclusion

A. Summary of Key Features and Benefits

Glass glaze resistors offer a unique combination of high temperature stability, excellent electrical performance, environmental resistance, mechanical strength, and low noise characteristics. These features make them a valuable component in a wide range of electronic applications.

B. Future Trends in Glass Glaze Resistor Technology

As technology continues to advance, the demand for more reliable and efficient electronic components will grow. Future trends may include further enhancements in materials and manufacturing processes, leading to even better performance and customization options for glass glaze resistors.

C. Final Thoughts on the Role of Glass Glaze Resistors in Modern Electronics

In conclusion, glass glaze resistors play a vital role in modern electronics, providing essential functionality in various applications. Their unique features and advantages make them a preferred choice for engineers and designers seeking reliable and high-performance resistors.

VIII. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Resistor Market Analysis Report

- Trends in Passive Components

C. Manufacturer Specifications and Data Sheets

- Manufacturer A: Glass Glaze Resistor Data Sheet

- Manufacturer B: Technical Specifications for Glass Glaze Resistors

This comprehensive overview of glass glaze resistors highlights their importance in electronic circuits, detailing their composition, features, advantages, limitations, and applications. As technology evolves, these resistors will continue to play a crucial role in the development of reliable and efficient electronic devices.

Product Features of Glass Glaze Resistors

I. Introduction

A. Definition of Glass Glaze Resistors

Glass glaze resistors are a type of passive electronic component that provides resistance to the flow of electric current. They are characterized by a unique glass glaze coating that enhances their performance and durability. These resistors are widely used in various electronic applications due to their ability to maintain stable resistance values under varying environmental conditions.

B. Importance of Resistors in Electronic Circuits

Resistors play a crucial role in electronic circuits by controlling the flow of current, dividing voltages, and protecting sensitive components from excessive current. They are essential for ensuring the proper functioning of electronic devices, making their reliability and performance critical to overall circuit design.

C. Overview of Glass Glaze Technology

The glass glaze technology used in these resistors involves applying a glass-like coating to a substrate, which not only provides electrical insulation but also enhances the mechanical and thermal properties of the resistor. This technology has led to the development of resistors that can withstand extreme conditions, making them suitable for a wide range of applications.

II. Composition and Construction

A. Materials Used in Glass Glaze Resistors

1. Glass Glaze Material

The primary component of glass glaze resistors is the glass glaze itself, which is a mixture of silica, alumina, and other oxides. This material is chosen for its excellent insulating properties and ability to withstand high temperatures.

2. Conductive Elements

The conductive elements in glass glaze resistors typically include metal oxides or carbon-based materials. These elements are carefully selected to achieve specific resistance values and ensure reliable performance.

B. Manufacturing Process

1. Application of Glass Glaze

The manufacturing process begins with the application of the glass glaze material onto a ceramic substrate. This is usually done through a screen printing or spraying technique, ensuring an even coating.

2. Firing Process

Once the glaze is applied, the resistors undergo a firing process in a kiln. This step is crucial as it causes the glass to melt and bond with the substrate, creating a solid and durable structure.

3. Final Assembly

After firing, the resistors are cooled and undergo final assembly, which may include adding leads or terminals for integration into electronic circuits. Quality control measures are implemented to ensure that each resistor meets specified performance standards.

III. Key Features of Glass Glaze Resistors

A. High Temperature Stability

1. Thermal Characteristics

Glass glaze resistors exhibit excellent thermal stability, allowing them to operate effectively in high-temperature environments. They can typically withstand temperatures up to 200°C or more without significant changes in resistance.

2. Applications in High-Temperature Environments

This thermal stability makes glass glaze resistors ideal for applications in automotive, aerospace, and industrial equipment, where exposure to extreme temperatures is common.

B. Excellent Electrical Performance

1. Resistance Values and Tolerances

These resistors are available in a wide range of resistance values, with tight tolerances that ensure consistent performance. This precision is essential for applications requiring accurate current control.

2. Voltage Ratings

Glass glaze resistors can handle high voltage levels, making them suitable for use in power electronics and other high-voltage applications.

C. Environmental Resistance

1. Moisture and Humidity Resistance

The glass glaze coating provides excellent moisture and humidity resistance, preventing corrosion and degradation over time. This feature is particularly important in outdoor and humid environments.

2. Chemical Resistance

Glass glaze resistors are also resistant to various chemicals, making them suitable for use in harsh industrial settings where exposure to corrosive substances may occur.

D. Mechanical Strength

1. Durability and Longevity

The robust construction of glass glaze resistors ensures high durability and longevity, reducing the need for frequent replacements and maintenance.

2. Resistance to Mechanical Stress

These resistors can withstand mechanical stress, such as vibrations and shocks, making them ideal for applications in automotive and aerospace industries.

E. Low Noise Characteristics

1. Importance of Low Noise in Circuits

Low noise is a critical factor in many electronic applications, particularly in audio and precision measurement devices. Glass glaze resistors are designed to minimize electrical noise, ensuring clean signal transmission.

2. Comparison with Other Resistor Types

When compared to other resistor types, such as carbon composition resistors, glass glaze resistors exhibit significantly lower noise levels, making them a preferred choice in sensitive applications.

IV. Advantages of Glass Glaze Resistors

A. Versatility in Applications

1. Use in Consumer Electronics

Glass glaze resistors are commonly used in consumer electronics, including televisions, computers, and audio equipment, where reliability and performance are paramount.

2. Industrial Applications

In industrial settings, these resistors are utilized in control systems, automation equipment, and power supplies, where their durability and environmental resistance are advantageous.

3. Automotive and Aerospace Industries

The automotive and aerospace industries benefit from the high-temperature stability and mechanical strength of glass glaze resistors, making them suitable for critical applications in vehicles and aircraft.

B. Cost-Effectiveness

1. Comparison with Other Resistor Types

While glass glaze resistors may have a higher initial cost compared to some alternatives, their durability and long lifespan often result in lower overall costs in the long run.

2. Long-Term Savings

The reduced need for replacements and maintenance contributes to long-term savings, making glass glaze resistors a cost-effective choice for many applications.

C. Customization Options

1. Tailored Resistance Values

Manufacturers can produce glass glaze resistors with specific resistance values tailored to meet the unique requirements of various applications.

2. Specific Size and Shape Configurations

Customization extends to size and shape, allowing designers to integrate these resistors seamlessly into their circuit designs.

V. Limitations of Glass Glaze Resistors

A. Potential Drawbacks

1. Size Constraints

One limitation of glass glaze resistors is their size. They may not be suitable for applications requiring very compact components, as their construction can be bulkier than other resistor types.

2. Limited Availability in Certain Markets

In some regions, glass glaze resistors may not be as readily available as other types, potentially limiting their use in specific applications.

B. Comparison with Alternative Resistor Technologies

1. Metal Film Resistors

Metal film resistors offer high precision and low noise but may not match the thermal stability and environmental resistance of glass glaze resistors.

2. Carbon Composition Resistors

While carbon composition resistors are cost-effective, they typically have higher noise levels and lower temperature stability compared to glass glaze resistors.

VI. Applications of Glass Glaze Resistors

A. Overview of Common Applications

Glass glaze resistors are utilized in a variety of applications, including consumer electronics, industrial equipment, automotive systems, and aerospace technology. Their unique features make them suitable for environments where reliability and performance are critical.

B. Case Studies

1. Consumer Electronics

In consumer electronics, glass glaze resistors are used in power supply circuits, audio amplifiers, and signal processing devices, where their low noise and stability enhance overall performance.

2. Industrial Equipment

In industrial equipment, these resistors are employed in control systems and automation devices, ensuring reliable operation in demanding environments.

3. Automotive Systems

In automotive systems, glass glaze resistors are used in engine control units and safety systems, where their high-temperature stability and mechanical strength are essential.

VII. Conclusion

A. Summary of Key Features and Benefits

Glass glaze resistors offer a unique combination of high temperature stability, excellent electrical performance, environmental resistance, mechanical strength, and low noise characteristics. These features make them a valuable component in a wide range of electronic applications.

B. Future Trends in Glass Glaze Resistor Technology

As technology continues to advance, the demand for more reliable and efficient electronic components will grow. Future trends may include further enhancements in materials and manufacturing processes, leading to even better performance and customization options for glass glaze resistors.

C. Final Thoughts on the Role of Glass Glaze Resistors in Modern Electronics

In conclusion, glass glaze resistors play a vital role in modern electronics, providing essential functionality in various applications. Their unique features and advantages make them a preferred choice for engineers and designers seeking reliable and high-performance resistors.

VIII. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Resistor Market Analysis Report

- Trends in Passive Components

C. Manufacturer Specifications and Data Sheets

- Manufacturer A: Glass Glaze Resistor Data Sheet

- Manufacturer B: Technical Specifications for Glass Glaze Resistors

This comprehensive overview of glass glaze resistors highlights their importance in electronic circuits, detailing their composition, features, advantages, limitations, and applications. As technology evolves, these resistors will continue to play a crucial role in the development of reliable and efficient electronic devices.